.gif)

Baffle (heat exchanger)

Encyclopedia

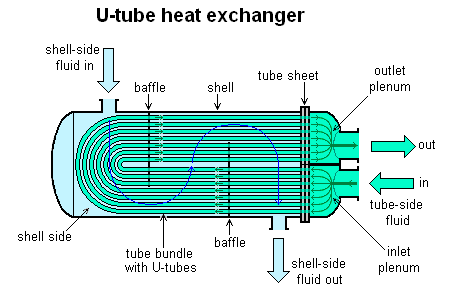

Baffles are flow-directing or obstructing vanes or panels used in some industrial process

Industrial process

Industrial processes are procedures involving chemical or mechanical steps to aid in the manufacture of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry....

vessels (tanks), such as shell and tube heat exchanger

Shell and tube heat exchanger

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell with a...

s, chemical reactor

Chemical reactor

In chemical engineering, chemical reactors are vessels designed to contain chemical reactions. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction...

s, and static mixer

Static mixer

A static mixer is a device for mixing two fluid materials. Most commonly, the fluids are liquid; however, static mixers are used to mix gas streams, disperse gas into liquid or disperse immiscible liquids. The device consists of mixer elements contained in a cylindrical or squared housing. These...

s. Baffles are an integral part of the shell and tube heat exchanger design. A baffle is designed to support tube bundles and direct the flow of fluid

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

s for maximum efficiency.

Use of baffles

The main roles of a baffle in a shell and tube heat exchanger are to:- Hold tubes in position (preventing sagging), both in production and operation

- Prevent the effects of vibrationVibrationVibration refers to mechanical oscillations about an equilibrium point. The oscillations may be periodic such as the motion of a pendulum or random such as the movement of a tire on a gravel road.Vibration is occasionally "desirable"...

, which is increased with both fluid velocity and the length of the exchanger - Direct shell-side fluid flow along tube field. This increases fluid velocity and the effective heat transferHeat transferHeat transfer is a discipline of thermal engineering that concerns the exchange of thermal energy from one physical system to another. Heat transfer is classified into various mechanisms, such as heat conduction, convection, thermal radiation, and phase-change transfer...

co-efficient of the exchanger

In a static mixer, baffles are used to promote mixing

Mixing (process engineering)

In industrial process engineering, mixing is a unit operation that involves manipulating a heterogeneous physical system, with the intent to make it more homogeneous...

.

In a chemical reactor, baffles are often attached to the interior walls to promote mixing and thus increase heat transfer

Heat transfer

Heat transfer is a discipline of thermal engineering that concerns the exchange of thermal energy from one physical system to another. Heat transfer is classified into various mechanisms, such as heat conduction, convection, thermal radiation, and phase-change transfer...

and possibly chemical reaction rate

Reaction rate

The reaction rate or speed of reaction for a reactant or product in a particular reaction is intuitively defined as how fast or slow a reaction takes place...

s.

Types of baffles

Implementation of baffles is decided on the basis of size, cost and their ability to lend support to the tube bundles and direct flow. Often this is linked to available pressure dropPressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

and the size and number of passes within the exchanger. Special allowances/changes are also made for finned

Fin (extended surface)

In the study of heat transfer, a fin is a surface that extends from an object to increase the rate of heat transfer to or from the environment by increasing convection. The amount of conduction, convection, or radiation of an object determines the amount of heat it transfers...

tubes. The different types of baffles include:

- Segmental Baffles (of which single segment is the most common)

- Rod or Bar Baffles (giving a uniform shell-side flow)

- Helical Baffles (similar to segmental with less pressure drop for same size exchanger)

- Longitudinal Flow Baffles (used in a two-pass shell)

- Impingement Baffles (used for protecting bundle when entrance velocity is high)

- Orifice Baffles.