Ultrasonic inspection

Encyclopedia

Ultrasound

Ultrasound is cyclic sound pressure with a frequency greater than the upper limit of human hearing. Ultrasound is thus not separated from "normal" sound based on differences in physical properties, only the fact that humans cannot hear it. Although this limit varies from person to person, it is...

pulse-waves with center frequencies ranging from 0.1-15 MHz and occasionally up to 50 MHz are launched into materials to detect internal flaws or to characterize materials. The technique is also commonly used to determine the thickness of the test object, for example, to monitor pipework corrosion.

Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is a form of non-destructive testing used in many industries including aerospace

Aerospace

Aerospace comprises the atmosphere of Earth and surrounding space. Typically the term is used to refer to the industry that researches, designs, manufactures, operates, and maintains vehicles moving through air and space...

, automotive and other transportation sectors.

How it works

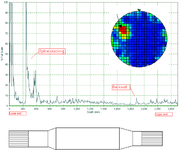

In ultrasonic testing, an ultrasound transducer connected to a diagnostic machine is passed over the object being inspected. The transducer is typically separated from the test object by a couplant (such as oil) or by water, as in immersion testing.There are two methods of receiving the ultrasound waveform, reflection and attenuation. In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the "sound" is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude

Amplitude

Amplitude is the magnitude of change in the oscillating variable with each oscillation within an oscillating system. For example, sound waves in air are oscillations in atmospheric pressure and their amplitudes are proportional to the change in pressure during one oscillation...

representing the intensity of the reflection and the distance, representing the arrival time of the reflection. In attenuation (or through-transmission) mode, a transmitter sends ultrasound through one surface, and a separate receiver detects the amount that has reached it on another surface after traveling through the medium. Imperfections or other conditions in the space between the transmitter and receiver reduce the amount of sound transmitted, thus revealing their presence. Using the couplant increases the efficiency of the process

by reducing the losses in the ultrasonic wave energy due to separation between the surfaces.

Advantages

- High penetrating power, which allows the detection of flaws deep in the part.

- High sensitivity, permitting the detection of extremely small flaws.

- Only one surface need be accessible.

- Greater accuracy than other nondestructive methods in determining the depth of internal flaws and the thickness of parts with parallel surfaces.

- Some capability of estimating the size, orientation, shape and nature of defects.

- Nonhazardous to operations or to nearby personnel and has no effect on equipment and materials in the vicinity.

- Capable of portable or highly automated operation.

Disadvantages

- Manual operation requires careful attention by experienced technicians

- Extensive technical knowledge is required for the development of inspection procedures.

- Parts that are rough, irregular in shape, very small or thin, or not homogeneous are difficult to inspect.

- Surface must be prepared by cleaning and removing loose scale, paint, etc., although paint that is properly bonded to a surface need not be removed.

- Couplants are needed to provide effective transfer of ultrasonic wave energy between transducers and parts being inspected unless a non-contact technique is used. Non-contact techniques include Laser and Electro Magnetic Acoustic Transducers (EMAT).

- Inspected items must be water resistant, when using water based couplants that do not contain rust inhibitors.

Standards

International Organization for StandardizationInternational Organization for Standardization

The International Organization for Standardization , widely known as ISO, is an international standard-setting body composed of representatives from various national standards organizations. Founded on February 23, 1947, the organization promulgates worldwide proprietary, industrial and commercial...

(ISO)

- ISO 7963, Non-destructive testing - Ultrasonic testing - Specification for calibration block No. 2

- ISO/DIS 11666, Non-destructive testing of welds - Ultrasonic testing of welded joints - Acceptance levels

- ISO/DIS 17640, Non-destructive testing of welds - Ultrasonic testing of welded joints

- ISO 22825, Non-destructive testing of welds - Ultrasonic testing - Testing of welds in austenitic steels and nickel-based alloys

European Committee for Standardization

European Committee for Standardization

The European Committee for Standardization or Comité Européen de Normalisation , is a non-profit organisation whose mission is to foster the European economy in global trading, the welfare of European citizens and the environment by providing an efficient infrastructure to interested parties for...

(CEN)

- EN 583, Non-destructive testing - Ultrasonic examination

- EN 1330-4, Non destructive testing - Terminology - Part 4: Terms used in ultrasonic testing

- EN 1712, Non-destructive testing of welds - Ultrasonic testing of welded joints - Acceptance levels

- EN 1713, Non-destructive testing of welds - Ultrasonic testing - Characterization of indications in welds

- EN 1714, Non-destructive testing of welds - Ultrasonic testing of welded joints

- EN 12223, Non-destructive testing - Ultrasonic examination - Specification for calibration block No. 1

- EN 12668-1, Non-destructive testing - Characterization and verification of ultrasonic examination equipment - Part 1: Instruments

- EN 12668-2, Non-destructive testing - Characterization and verification of ultrasonic examination equipment - Part 2: Probes

- EN 12668-3, Non-destructive testing - Characterization and verification of ultrasonic examination equipment - Part 3: Combined equipment

- EN 12680, Founding - Ultrasonic examination

- EN 14127, Non-destructive testing - Ultrasonic thickness measurement

See also

- Non-Contact UltrasoundNon-Contact UltrasoundNon-Contact Ultrasound is a method of non-destructive testing where ultrasound is generated and used to test materials without the generating sensor making direct or indirect contact with the test material or test subject. Historically this has been difficult to do, as a typical transducer is very...

- Phased array ultrasonicsPhased array ultrasonicsPhased Array ultrasonics is an advanced method of ultrasonic testing that has applications in medical imaging and industrial nondestructive testing. In medicine a common application of phased array is the imaging of the heart...

- Time of flight diffraction ultrasonicsTime of flight diffraction ultrasonicsTime of Flight Diffraction method of Ultrasonic inspection is a very sensitive and accurate method for nondestructive testing of welds for defects. TOFD originated from tip diffraction techniques which were first published by Silk and Liddington in 1975 which paved the way for TOFD. Later works...

(TOFD) - Time of Flight Ultrasonic Determination of 3D Elastic ConstantsTime of Flight Ultrasonic Determination of 3D Elastic ConstantsThe three dimensional elastic constants of materials can be measured using the ultrasonic immersion method. This was pioneered by xx and xx from the National Physical Laboratory in the 19xxs. It has mainly been used for polymer composite materials...

(TOF) - Internal rotary inspection systemInternal rotary inspection systemInternal rotary inspection system is an ultrasonic method for the nondestructive testing of pipes and tubes. The IRIS probe is inserted into a tube that is flooded with water, and the probe is pulled out slowly as the data is displayed and recorded...

(IRIS) ultrasonics for tubes - EMAT Electromagnetic Acoustic Transducer

- ART (Acoustic Resonance Technology)ART (Acoustic Resonance Technology)Acoustic Resonance Technology is an acoustic inspection technology developed by Det Norske Veritas over the past 20 years. ART exploits the phenomenon of half-wave resonance, whereby a suitably excited resonant target exhibits longitudinal resonances at certain frequencies characteristic of the...

Further reading

- Albert S. Birks, Robert E. Green, Jr., technical editors ; Paul McIntire, editor. Ultrasonic testing, 2nd ed. Columbus, OH : American Society for Nondestructive TestingAmerican Society for Nondestructive TestingThe American Society for Nondestructive Testing, Inc. or ASNT is a technical society for nondestructive testing professionals. ASNT evolved from The American Industrial Radium and X-Ray Society which was founded in 1941. Its headquarters is located in Columbus, OH, and there are 70 local sections...

, 1991. ISBN 0931403049. - Josef Krautkrämer, Herbert Krautkrämer. Ultrasonic testing of materials, 4th fully rev. ed. Berlin; New York: Springer-Verlag, 1990. ISBN 3540512314.

- J.C. Drury. Ultrasonic Flaw Detection for Technicians, 3rd ed., UK: Silverwing Ltd. 2004. (See Chapter 1 online (PDF, 61 kB)).

- Nondestructive Testing Handbook, Third ed.: Volume 7, Ultrasonic Testing. Columbus, OH: American Society for Nondestructive Testing.

- Detection and location of defects in electronic devices by means of scanning ultrasonic microscopy and the wavelet transform measurement, Volume 31, Issue 2, March 2002, Pages 77–91, L. Angrisani, L. Bechou, D. Dallet, P. Daponte, Y. Ousten