Stock removal

Encyclopedia

High stock removal is a technological process with the goal to remove large / substantial amounts of material. The quantity of material, which can be removed in a specific process, depends on the material properties and the machining tool used.

(e). This is the amount of energy required to cut a volume of work material (kWh/mm3). Specific energy is depending on material properties. This makes that stock removal is related to specific energy.

Not only the material properties determine the energy required to cut a volume of material (specific energy). The needed energy also depends on the technological process used to process the work material.

Not only the material properties determine the energy required to cut a volume of material (specific energy). The needed energy also depends on the technological process used to process the work material.

, turning

, broaching, milling

and grinding

. Turning and milling are conventionally the most popular machining technologies. Turning is mainly used for round products, milling has a broad range of applications. Conventional methods like milling do have problems to keep up with the developments of the ‘difficult to machine’ materials. These methods generate locally too much heat. The special materials in particular require a cool cutting process.

Recently grinding with coated abrasives

Recently grinding with coated abrasives

has become a viable alternative for high stock removal by some major developments in the field of the machine tool and grinding belt.

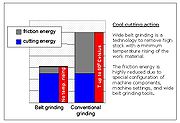

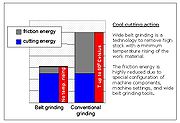

High stock belt grinding is a cool cutting process. The amount of friction energy is significantly lower compared to other (bonded) grinding techniques. The reason is that the amount of rubbing and ploughing energies are greatly reduced due to special configuration of machine components, machine settings, and wide belt grinding

tools. The productivity of the abrasive belt grinding technology is in most cases three times that of the rotary or reciprocating vertical grinders. As a result of this belt grinding is replacing the conventional technologies in the field of the specialty metals. As an example the world biggest titanium manufactures are using the belt grinding techniques.

Materials

The stock removal rate or the possible removal of material in a specific time period is depending on material properties. This is expressed by the machinability of a material: the ease or difficulty to machine a particular material. The machinability of materials varies greatly, for instance, aluminium and magnesium have a high machinability ratio compared to titanium and other special metals.Specific energy

One way of qualifying the machinability is the specific energySpecific energy

Specific energy is defined as the energy per unit mass. Common metric units are J/kg. It is an intensive property. Contrast this with energy, which is an extensive property. There are two main types of specific energy: potential energy and specific kinetic energy. Others are the gray and sievert,...

(e). This is the amount of energy required to cut a volume of work material (kWh/mm3). Specific energy is depending on material properties. This makes that stock removal is related to specific energy.

New materials

There is a continuously development of new materials to fulfill the extreme demands of market segments like, Petrochemical, Power/Energy and Aerospace. Metallurgical changes have improved a large range of these materials (titanium, nickel). But by making the materials harder tougher, less heat sensitive and/or more resistant to corrosion and fatigue, this also make these new developed materials hard to machine.Temperature rising

The specific cutting energy needed for ‘difficult to machine’ materials are extremely high. Especially in the high stock removal applications there are problems with the temperature rising of the work material surface. An increase of the work material temperature leads to deterioration of the work material surface integrity. Resulting in metallurgical damages like micro cracks, residual stresses and work hardening.High stock removal machine tools

Technologies

A lot of technologies are capable of removing substantial amounts of material. Among them are: sawingSawing

The execution by sawing was a method of execution used in Europe under the Roman Empire, in the Middle East, and in parts of Asia. Some sources say that the method was probably never used. The condemned were hung upside-down and sawn apart vertically through the middle, starting at the groin...

, turning

Turning

Turning is the process whereby a single point cutting tool is parallel to the surface. It can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using a computer controlled and automated lathe which does not. This type of...

, broaching, milling

Milling machine

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

and grinding

Grinding (abrasive cutting)

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.A wide variety of machines are used for grinding:* Hand-cranked knife-sharpening stones * Handheld power tools such as angle grinders and die grinders...

. Turning and milling are conventionally the most popular machining technologies. Turning is mainly used for round products, milling has a broad range of applications. Conventional methods like milling do have problems to keep up with the developments of the ‘difficult to machine’ materials. These methods generate locally too much heat. The special materials in particular require a cool cutting process.

Grinding

Traditionally bonded abrasives are used for stock removal. To grind large products, with a substantial material removal, vertical segment grinders are used. These grinding machines work with a rotating disc with abrasive segments. The work material is pressed against those segments with the aid of a rotating or reciprocating table. These technologies are using significantly greater power, up to 450 hp, than other grinding methods. Some major manufactures of these machines are Blanchard, Mattison, Göckel and Reform.Belt grinding

Coated abrasives

A coated abrasive is an abrasive grain bonded to a flexible substrate using adhesives. Common substrates are paper, cloth, vulcanized fiber, and plastic films and come in grit sizes range from very coarse to ultrafine...

has become a viable alternative for high stock removal by some major developments in the field of the machine tool and grinding belt.

High stock belt grinding is a cool cutting process. The amount of friction energy is significantly lower compared to other (bonded) grinding techniques. The reason is that the amount of rubbing and ploughing energies are greatly reduced due to special configuration of machine components, machine settings, and wide belt grinding

Belt grinding

Belt grinding is a machining method to process metals and other materials with the aid of coated abrasives.The basic difference between belt grinders and belt sanders is the material being machined. Sanding is the machining of wood, grinding is the common name for machining...

tools. The productivity of the abrasive belt grinding technology is in most cases three times that of the rotary or reciprocating vertical grinders. As a result of this belt grinding is replacing the conventional technologies in the field of the specialty metals. As an example the world biggest titanium manufactures are using the belt grinding techniques.