Stirling engine

Overview

Heat engine

In thermodynamics, a heat engine is a system that performs the conversion of heat or thermal energy to mechanical work. It does this by bringing a working substance from a high temperature state to a lower temperature state. A heat "source" generates thermal energy that brings the working substance...

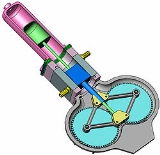

operating by cyclic compression and expansion of air or other gas, the working fluid

Working fluid

A working fluid is a pressurized gas or liquid that actuates a machine. Examples include steam in a steam engine, air in a hot air engine and hydraulic fluid in a hydraulic motor or hydraulic cylinder...

, at different temperature levels such that there is a net conversion of heat

Heat

In physics and thermodynamics, heat is energy transferred from one body, region, or thermodynamic system to another due to thermal contact or thermal radiation when the systems are at different temperatures. It is often described as one of the fundamental processes of energy transfer between...

energy to mechanical work.

Like the steam engine, the Stirling engine is traditionally classified as an external combustion engine

External combustion engine

An external combustion engine is a heat engine where an working fluid is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid then, by expanding and acting on the mechanism of the engine, produces motion and usable work...

, as all heat transfers to and from the working fluid take place through the engine wall.

Unanswered Questions