Stereolithography

Encyclopedia

Technology description

Ultraviolet

Ultraviolet light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm, and energies from 3 eV to 124 eV...

curable

Curing (chemistry)

Curing is a term in polymer chemistry and process engineering that refers to the toughening or hardening of a polymer material by cross-linking of polymer chains, brought about by chemical additives, ultraviolet radiation, electron beam or heat...

photopolymer

Photopolymer

A photopolymer is a polymer that changes its properties when exposed to light, often in the ultraviolet spectrum. These polymers are useful in dentistry for fillings and in rapid prototyping in the stereolithography and 3D printing processes. This material is also used in the creation of ADA...

"resin

Resin

Resin in the most specific use of the term is a hydrocarbon secretion of many plants, particularly coniferous trees. Resins are valued for their chemical properties and associated uses, such as the production of varnishes, adhesives, and food glazing agents; as an important source of raw materials...

" and a UV

Ultraviolet

Ultraviolet light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm, and energies from 3 eV to 124 eV...

laser

Laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of photons. The term "laser" originated as an acronym for Light Amplification by Stimulated Emission of Radiation...

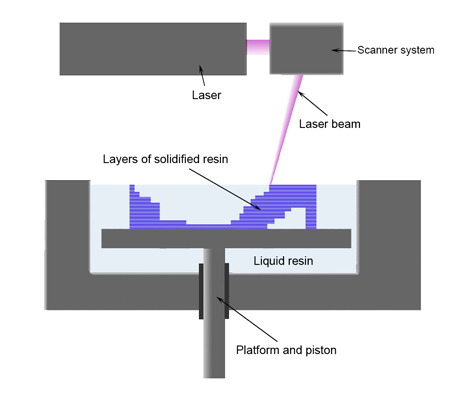

to build parts a layer at a time. On each layer, the laser beam traces a part cross-section pattern on the surface of the liquid resin. Exposure to the UV

Ultraviolet

Ultraviolet light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm, and energies from 3 eV to 124 eV...

laser

Laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of photons. The term "laser" originated as an acronym for Light Amplification by Stimulated Emission of Radiation...

light cures

Curing (chemistry)

Curing is a term in polymer chemistry and process engineering that refers to the toughening or hardening of a polymer material by cross-linking of polymer chains, brought about by chemical additives, ultraviolet radiation, electron beam or heat...

, solidifies the pattern traced on the resin and adheres it to the layer below.

After a pattern has been traced, the SLA's elevator platform descends by a single layer thickness, typically 0.05 mm to 0.15 mm (0.002" to 0.006"). Then, a resin-filled blade sweeps across the part cross section, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, adhering to the previous layer. A complete 3-D

Three-dimensional space

Three-dimensional space is a geometric 3-parameters model of the physical universe in which we live. These three dimensions are commonly called length, width, and depth , although any three directions can be chosen, provided that they do not lie in the same plane.In physics and mathematics, a...

part is formed by this process. After building, parts are cleaned of excess resin by immersion in a chemical bath and then cured

Curing (chemistry)

Curing is a term in polymer chemistry and process engineering that refers to the toughening or hardening of a polymer material by cross-linking of polymer chains, brought about by chemical additives, ultraviolet radiation, electron beam or heat...

in a UV

Ultraviolet

Ultraviolet light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range 10 nm to 400 nm, and energies from 3 eV to 124 eV...

oven.

Stereolithography requires the use of support structures to attach the part to the elevator platform and to prevent certain geometry from not only deflecting due to gravity, but to also accurately hold the 2-D cross sections in place such that they resist lateral pressure from the re-coater blade. Supports are generated automatically during the preparation of 3-D CAD models for use on the stereolithography machine, although they may be manipulated manually. Supports must be removed from the finished product manually; this is not true for all rapid prototyping

Rapid prototyping

Rapid prototyping is the automatic construction of physical objects using additive manufacturing technology. The first techniques for rapid prototyping became available in the late 1980s and were used to produce models and prototype parts. Today, they are used for a much wider range of applications...

technologies.

This process is a more expensive form of rapid prototyping.

Advantages and disadvantages

Stereolithography has many common names such as: 3D printing3D printing

3D printing is a form of additive manufacturing technology where a three dimensional object is created by laying down successive layers of material. 3D printers are generally faster, more affordable, and easier to use than other additive manufacturing technologies. However, the term 3D printing is...

, optical fabrication, photo-solidification, solid free-form fabrication and solid imaging. One of the appealing aspects about SL is that a functional part can be created within one day. The length of time it takes to produce any one part depends on the size and complexity of the project and can take anywhere from a few hours to more than a day. Most SL machines can produce parts with a maximum size of approximately 50 cm x 50 cm x 60 cm (20" x 20" x 24") and some, such as the Mammoth stereolithograhy machine, are capable of producing parts of more than 2m in a single piece(the Mammoth has a build platform of 210 cm x 70 cm x 80 cm). Prototypes made by stereolithography can be very beneficial as they are strong enough to be machined and can be used as master patterns for injection molding, thermoforming, blow molding, and also in various metal casting processes. Although stereolithography can produce a wide variety of shapes, the process is often expensive - the photo-curable resin costs anywhere from $80 to $210 per litre. A stereolithography machine can cost from about $100,000 to more than $500,000.

History

The term “stereolithography” was coined in 1986 by Charles (Chuck) W. HullChuck Hull

Chuck Hull is the co-founder, executive vice president and chief technology officer of 3D Systems. He is the inventor of the solid imaging process known as stereolithography, the first commercial rapid prototyping technology, and the STL file format. He is the inventor on more than 60 U.S...

. Stereolithography was defined as a method and apparatus for making solid objects by successively “printing” thin layers of the ultraviolet curable material one on top of the other. Hull described a concentrated beam of ultraviolet light focused onto the surface of a vat filled with liquid photopolymer

Photopolymer

A photopolymer is a polymer that changes its properties when exposed to light, often in the ultraviolet spectrum. These polymers are useful in dentistry for fillings and in rapid prototyping in the stereolithography and 3D printing processes. This material is also used in the creation of ADA...

. The light beam draws the object onto the surface of the liquid layer by layer, causing polymerization or crosslinking to give a solid. Because of the complexity of the process, it must be computer-controlled. In 1986 Chuck Hull

Chuck Hull

Chuck Hull is the co-founder, executive vice president and chief technology officer of 3D Systems. He is the inventor of the solid imaging process known as stereolithography, the first commercial rapid prototyping technology, and the STL file format. He is the inventor on more than 60 U.S...

Founded the first company to generalize and commercialize this procedure, 3D Systems Inc, which is currently based in Rock Hill, SC.

More recently, attempts have been made at constructing mathematical models of the stereolithography process, and designing algorithms that will automatically determine whether or not a proposed object may be constructed by this process.

External links

- Graphical Display of the Stereolithography Process: A resource page maintained by Laser Prototypes (Europe) Ltd,

- Castle Island's Worldwide Guide to Rapid Prototyping, with comprehensive information on rapid prototyping, rapid tooling, stereolithography and solid freeform fabrication technology products and services. Complete rapid prototyping service bureau listings.

- How Stereolithography (3-D Layering) Works from HowStuffWorks.com

- Manufacturing Engineering Centre (MEC), Cardiff University, UK

- Rapid Prototyping and Stereolithography animation - Animation demonstrates stereolithography and the actions of an SL machine.

- About 3D Systems, Company History