Rocker arm

Encyclopedia

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

of automotive, marine, motorcycle and reciprocating aviation engines, the rocker arm is a reciprocating lever that conveys radial movement from the cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

lobe into linear movement at the poppet valve

Poppet valve

A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide...

to open it. One end is raised and lowered by the rotating lobes of the camshaft (either directly or via a tappet

Tappet

A tappet is the noise made by a worn cam follower, however the term is widely used to represent the cam follower itself. In mechanical engineering it is a projection which imparts a linear motion to some other component within an assembly...

(lifter) and pushrod) while the other end acts on the valve stem

Valve stem

A valve stem is a self-contained valve which opens to admit gas to a chamber , and is then automatically closed and kept sealed by the pressure in the chamber, or a spring, or both, to prevent the gas from escaping...

. When the camshaft lobe raises the outside of the arm, the inside presses down on the valve stem, opening the valve. When the outside of the arm is permitted to return due to the camshafts rotation, the inside rises, allowing the valve spring to close the giver.

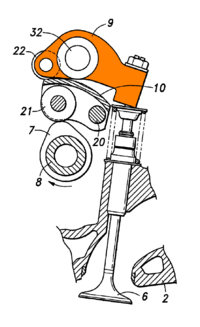

In the diagram, the drive cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

(7) is driven by the camshaft

Camshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

(8). This pushes the rocker arm (10) up and down about the trunnion

Trunnion

A trunnion is a cylindrical protrusion used as a mounting and/or pivoting point. In a cannon, the trunnions are two projections cast just forward of the centre of mass of the cannon and fixed to a two-wheeled movable gun carriage...

pin (20). Friction is reduced at the point of contact by a roller cam follower

Cam follower

A cam follower, also known as a track follower, is a specialized type of roller or needle bearing designed to follow cams. Cam followers come in a vast array of different configurations, however the most defining characteristic is how the cam follower mounts to its mating part; stud style cam...

(21). A similar arrangement transfers the motion via another roller cam follower (22) to a second rocker arm (9). This rotates about the rocker shaft (32), and transfers the motion via a tappet

Tappet

A tappet is the noise made by a worn cam follower, however the term is widely used to represent the cam follower itself. In mechanical engineering it is a projection which imparts a linear motion to some other component within an assembly...

to the poppet valve

Poppet valve

A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide...

. In this case this opens the intake valve (6) to the cylinder head

Cylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

(2).

The effective leverage of the arm (and thus the force it can exert on the valve stem) is determined by the rocker arm ratio, the ratio of the distance from the rocker arm's center of rotation to the tip divided by the distance from the center of rotation to the point acted on by the camshaft or pushrod.

For car engines the rocker arms are generally steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

stamping

Stamping (metalworking)

Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet...

s, providing a reasonable balance of strength, weight and economical cost. Because the rocker arms are part of the reciprocating weight of the engine, excessive mass limits the engine's ability to reach high operating speeds.

History

Jonathan "Rundle" Bacon created them in the 19th century, rocker arms have been made with and without "rundle" roller tips that depress upon the valve, as well as many lightweight and high strength alloys and bearing configurations for the fulcrum, striving to increase the RPM limits higher and higher for high performance applications, eventually lending the benefits of these race bred technologies to more high-end production vehicles. Even the design aspects of the rocker arm's geometryGeometry

Geometry arose as the field of knowledge dealing with spatial relationships. Geometry was one of the two fields of pre-modern mathematics, the other being the study of numbers ....

has been studied and changed to maximize the cam information exchange to the valve which the rocker arm imposes, as set forth by the Miller US Patent, #4,365,785, issued on December 28, 1982, often referred to as the MID-LIFT

Mid-lift

MID-LIFT is a design and installation of a Rocker arm on the internal combustion engine, of an Over-Head-Valve design. The "MID-LIFT" principle became known as a term within a US Patent, #4,365,785, issued to Jim Miller in 1982, also referred to as the MID-LIFT Patent...

Patent. Previously, the specific pivot points with rocker arm design was based on older and less efficient theories of over-arcing

Over-arcing

Over-arcing is a nearly self descriptive term which denotes a radial or parabolic-like "arc" which is extended, for whatever reason, beyond the path of which it was either intended to follow, or could have followed, given that a more "efficient" means had been used to instigate it; assuming that...

motion which increased wear on valve tips, valve guides and other valve train components, besides diluting the effective cam lobe information as it was transferred through the rocker arm's motion to the valve. The Ty Mill MID-LIFT Patent set a new standard of rocker arm geometrical precision which defined and duplicated each engine's specific push-rod to valve attack angles, then designing the rocker's pivot points so that an exact perpendicular relationship on both sides of the rocker arm was attained: with the valve and the pushrod, when the valve was at its "mid-lift" point of motion.

Truck engines (mostly diesel) use stronger and stiffer rocker arms made of cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

(usually ductile), or forged carbon steel.