Rework

Encyclopedia

Area array package

An area array package is chip package where the interconnection terminals are placed on the surface area, providing a greater number of connections than where only the outer perimeter is used.The first chip package of this kind was a ceramic pin grid array....

s such as Ball grid array

Ball grid array

A ball grid array is a type of surface-mount packaging used for integrated circuits.- Description :The BGA is descended from the pin grid array , which is a package with one face covered with pins in a grid pattern. These pins conduct electrical signals from the integrated circuit to the printed...

(BGA) devices.

Reasons for rework

- Insufficient or excessive solder joints that are created during assembly operations.

- Defective devices.

- Engineering parts changes, upgrades, etc.

Hit the aim step by step

The value chain of rework

Afterwards the pad array on the conductor board is cleaned from old tin. It is quite easy to remove these rests by heating them up into the area of melting temperatures.

In principle the precise placement of the new unit onto the prepared pad array requires a high accurate vision alignment system with high resolution and magnification which is controlled by a skilled operator. The smaller the pitch of the components the higher the demand on the precision equipment for the alignment.

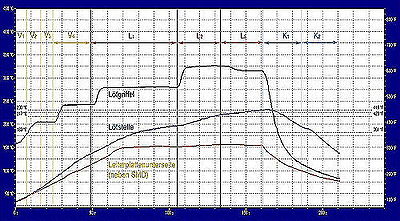

Finally the just now placed SMD is soldered on the board. Reliable and high quality solder joints are created by an adapted solder profile which heats all the connections between the unit and the PCBA up to the area of melting temperatures and cools them properly down.

Extras

High quality demands or specific designs of SMDs require the application of solder paste before positioning and soldering the unit. Consequently much technical effort is needed to apply the new tin where required in the manufacturing of the board.

Sometimes the desoldered BGA

Ball grid array

A ball grid array is a type of surface-mount packaging used for integrated circuits.- Description :The BGA is descended from the pin grid array , which is a package with one face covered with pins in a grid pattern. These pins conduct electrical signals from the integrated circuit to the printed...

or CSP

Chip scale package

A chip scale package is a type of integrated circuit chip carrier.Originally, CSP was the acronym for chip-size packaging. Since only a few packages are chip size, the meaning of the acronym was adapted to chip-scale packaging...

can be re-used. The solder balls are removed and the sites "dressed" using a variety of different techniques. Most commonly used are solder braid and a soldering iron or heat based vacuum-based extraction with new spheres provided to the adjacent joints. This operation is called “reballing”.

Reballing of a BGA can be done via several methods including:

1. Using a set of mechanical fixtures for both the balls and the solder paste or flux

2. Using a BGA "preform" with embedded balls corresponding to the device pattern

3. Using semi-automated or fully automated machinery

Results

Professional and high quality rework re-establishes the correct function of the electronic assembly. The durability of the control panel is just marginal affected by the correct accomplishment of the rework value chain. Therefore it is widespread in all sectors of the electronic industry. Manufacturer of communications-technologies, entertainment- and consumer-devices, industrial commodities, automobiles, medical technology, aerospace and other high power electronics, as well as their service providers take advantage of rework.See also

- Reflow ovenReflow ovenA reflow oven is a machine used primarily for reflow soldering of surface mount electronic components to printed circuit boards .- Infrared and convection ovens :...

- Thermal profiling-Soldering of electronic products

External links

- rework videos – Professional rework equipment for SMD

- rework machinery – Machinery for professional Rework

- Medium/Small Scale Rework Machinery – Machinery for Professional Rework

- Fraunhofer IZM – Training

- 9DesignOnline.com – BGA/ SMT Repair Options – Brief insight into re-work, re-ball and BGA/ SMT replacement.

Center for Bonding Technologies

- ipc.org – Engineering standards and guidelines of the IPC

- Soldering Tip Videos – Rework and Soldering Demonstration "How To" videos