Planishing

Encyclopedia

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

technique that involves finishing the surface by finely shaping and smoothing sheet metal

Sheet metal

Sheet metal is simply metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed of the material...

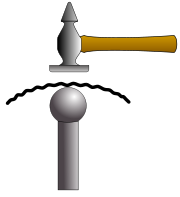

. This is by hammering with a planishing panel hammer or slapper file against shaped surface called a planishing stake that is held in a vice or a mounting hole in a blacksmith's beak anvil, or against hand held shaped metal tools that are known as Dollys or Anvils. The shape of the stake or dolly has to match the desired work piece contour, and so they come in a complex variety of shapes. Alternatively, planishing may be done by the use of an English Wheel

English Wheel

The English wheel, in Britain also known as a Wheeling machine, is a metalworking tool that enables a craftsman to form compound curves from flat sheets of metal such as aluminium or steel. The process of using an English wheel is known as Wheeling...

. Metal workers use planishing for surface finishing, after shaping and smoothing an object after approximately forming it, by stretching with other techniques, such as sinking and raising

Raising (metalwork)

Raising is a metalworking technique whereby sheet metal is formed over a stake or other solid object by repeated sequences or "passes" of hammering and annealing of the metal, thereby compressing and thickening the steel into the desired shape...

. Planishing is a hand driven process used in auto body repair and sheet metal

Sheet metal

Sheet metal is simply metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed of the material...

craft work such as medieval armor production.

Common tools used for planishing include panel beating hammers, slappers, and neck hammers Heavy rawhide or hardwood hammers, are often used. It is more difficult to make mistakes with heavy rawhide or wood mallets, but they are less effective for large imperfections. A worker, using repeated, relatively soft glancing blows, smooths the metal toward the curvature of the stake. If the metal begins to looks dimpled, the worker is using too much force in individual hammer blows.

Since planishing hammers are generally in contact with the outside surface of the piece, they are flat, have rounded edges and are polished to avoid marring the work. Pneumatic (air powered) Planishing Hammers strike hundreds of blows per minute.

Care must be taken not to allow sheet metal to work harden

Work hardening

Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation. This strengthening occurs because of dislocation movements within the crystal structure of the material. Any material with a reasonably high melting point such as metals and...

and become brittle during planishing. If it does, it must be annealed

Annealing (metallurgy)

Annealing, in metallurgy and materials science, is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the recrystallization temperature, maintaining a suitable temperature, and...

.