Oxo Biodegradable

Encyclopedia

Oxo Biodegradable plastic is polyolefin

plastic to which has been added amounts of metal salts. These catalyze the natural degradation process to speed it up so that the OXO plastic will degrade resulting in microfragments of plastic and metals which will remain in the environment but will not be seen as a visual contaminant.

The degradation process is shortened from hundreds of years to years and/or months for degradation and thereafter biodegradation

depends on the micro-organisms in the environment.

is a process that takes place in some materials. The speed depends on the environment.

Conventional polyethylene

(PE) and polypropylene

(PP) plastics will typically take hundreds of years to degrade. But oxo-degradable products utilize a prodegradant to speed up the molecular breakdown of the polyolefins and incorporate oxygen atoms into the resulting low molecular mass. This chemical change enables the micro breakdown of the plastics.

The process of degradation in OXO treated plastic is an oxidative chain scission that is catalyzed

The process of degradation in OXO treated plastic is an oxidative chain scission that is catalyzed

by metal salts leading to oxygenated (hydroxyl

ated and carboxylated) shorter chain molecules .

OXO plastic if discarded in the environment, will fragment and degrade to oxygenated low molecular weight (typically MW 5-10.000 amu

) within 2–18 months depending on the material (resin, thickness, anti-oxidants, etc.) and the temperature and other factors in the environment.

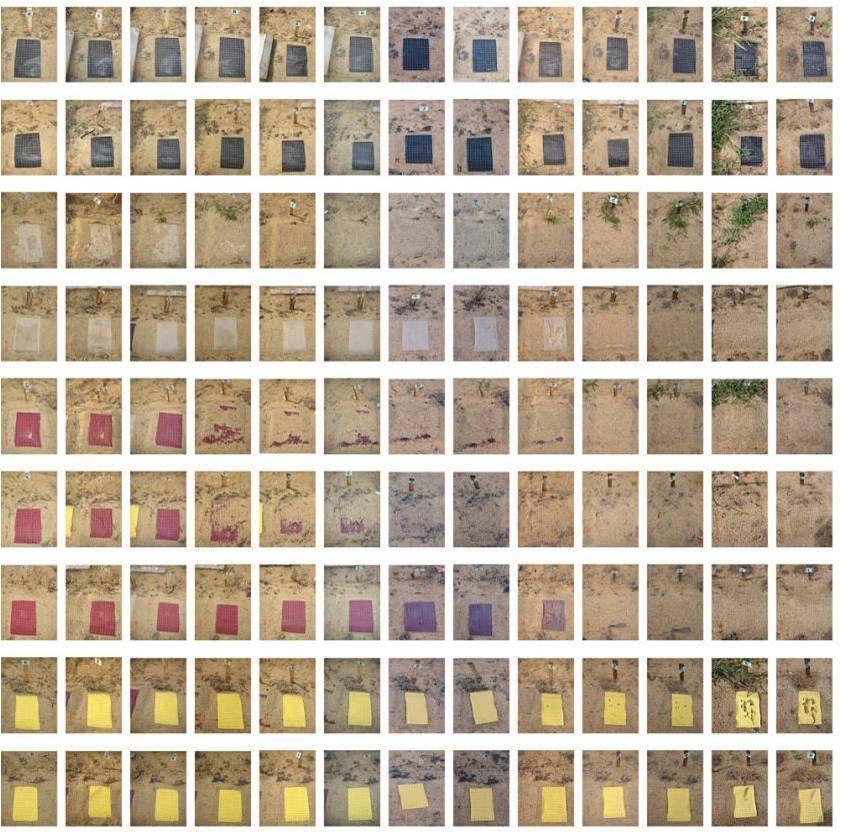

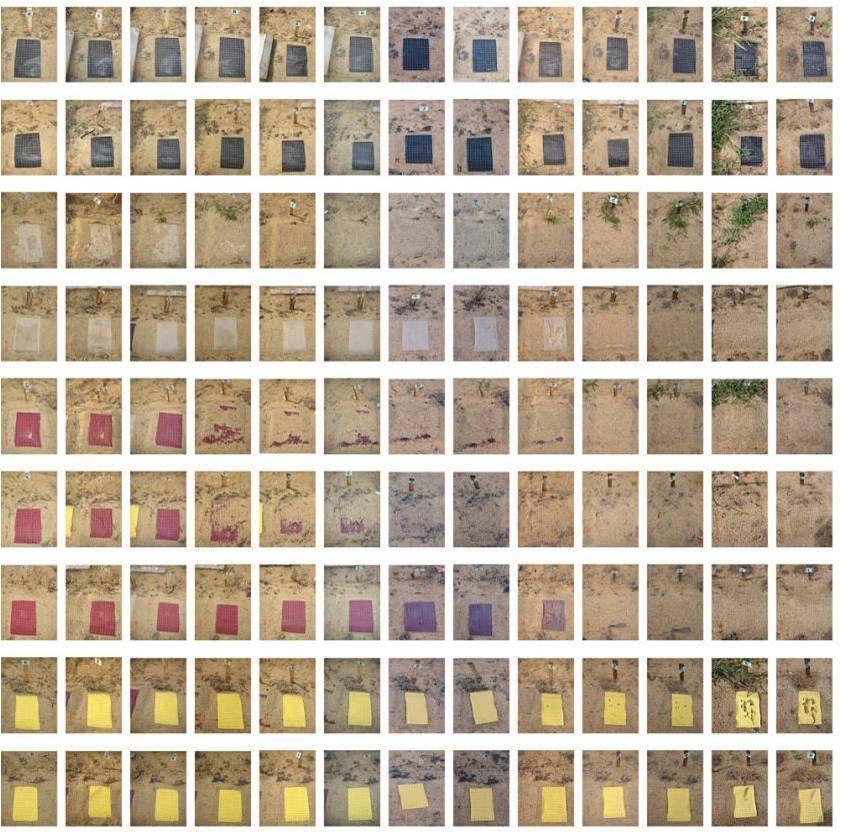

OXO plastics will not degrade in a landfill environment due to insufficient oxygen present below a depth of approximately 15 cm. A PE plastic bag for example 30 µm thick with 2% prodegradant additive degrades within 3 months if left exposed in an open air environment in Thailand and a 150 µm thick PP container or sheet will degrade within 3–6 months.

Oxo treated products do not degrade rapidly because they are stabilized to control the service-life of the product. They will nevertheless degrade more quickly than nature's wastes such as twigs and straw (c10 years) and much more quickly than ordinary plastic (many decades).

It is not compostable in industrial composting facilities according to the norm ASTM D6400.

This oxidation process takes longer than the 180 day period required by ASTM D6400 and similar standards for compostable plastics such as EN13432 and ISO 17088. This short time is necessary for compostable plastics because industrial composting has a short timescale, and is not the same as degradation in the environment. A leaf is generally considered to be biodegradable but it will not pass the composting standard due to the 180 day limit in ASTM D6400.

There is a Standard Guide (ASTM D6954-04) available which specifies procedures to test the degradability and to which some OXO complies. The ASTM Standard Guide is a 2-tier test procedure to determine whether a plastic could be marketed as "biodegradable". The Standard Guide references ASTM D5510 Test Specification which determines the usable life of the OXO plastic through Thermal Degradation. Secondly it also references ASTM D5208 which is used to determine the usable life based on UV degradation. These two test procedure in combination make up the 1-tier of the testing process for verifying a OXO plastic is degradable. After the 1-tier of testing is complete and the OXO plastic has been shown to be significantly degraded (usually done by FT-IR to show the new spectra peak at around the 1730 wavelength) the testing can move on to the 2-tier procedure. The ASTM Standards used for 2-tier testing are either ASTM D5338 or ASTM D5526. The specifications are both testing for the conversion of carbon in the polymer to CO2 in a control environment. After 60% carbon is converted from the sample the OXO plastic is said to have biodegraded. Although ASTM D6954-04 is only a Standard guide as opposed to a Standard Specification it does provide pass / fail criteria and therefore is useful in deciding whether a plastic could be marketed as "biodegradable". ASTM D6400 is a Standard Specification, but is appropriate only for compostable plastics. There is no need to refer to a Standard Specification unless a specific disposal route (e.g.: composting), is envisaged.

Polyolefin

A polyolefin is a polymer produced from a simple olefin as a monomer. For example, polyethylene is the polyolefin produced by polymerizing the olefin ethylene. An equivalent term is polyalkene; this is a more modern term, although polyolefin is still used in the petrochemical industry...

plastic to which has been added amounts of metal salts. These catalyze the natural degradation process to speed it up so that the OXO plastic will degrade resulting in microfragments of plastic and metals which will remain in the environment but will not be seen as a visual contaminant.

The degradation process is shortened from hundreds of years to years and/or months for degradation and thereafter biodegradation

Biodegradation

Biodegradation or biotic degradation or biotic decomposition is the chemical dissolution of materials by bacteria or other biological means...

depends on the micro-organisms in the environment.

Degradation process

DegradationChemical decomposition

Chemical decomposition, analysis or breakdown is the separation of a chemical compound into elements or simpler compounds. It is sometimes defined as the exact opposite of a chemical synthesis. Chemical decomposition is often an undesired chemical reaction...

is a process that takes place in some materials. The speed depends on the environment.

Conventional polyethylene

Polyethylene

Polyethylene or polythene is the most widely used plastic, with an annual production of approximately 80 million metric tons...

(PE) and polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

(PP) plastics will typically take hundreds of years to degrade. But oxo-degradable products utilize a prodegradant to speed up the molecular breakdown of the polyolefins and incorporate oxygen atoms into the resulting low molecular mass. This chemical change enables the micro breakdown of the plastics.

Catalysis

Catalysis is the change in rate of a chemical reaction due to the participation of a substance called a catalyst. Unlike other reagents that participate in the chemical reaction, a catalyst is not consumed by the reaction itself. A catalyst may participate in multiple chemical transformations....

by metal salts leading to oxygenated (hydroxyl

Hydroxyl

A hydroxyl is a chemical group containing an oxygen atom covalently bonded with a hydrogen atom. In inorganic chemistry, the hydroxyl group is known as the hydroxide ion, and scientists and reference works generally use these different terms though they refer to the same chemical structure in...

ated and carboxylated) shorter chain molecules .

OXO plastic if discarded in the environment, will fragment and degrade to oxygenated low molecular weight (typically MW 5-10.000 amu

Atomic mass unit

The unified atomic mass unit or dalton is a unit that is used for indicating mass on an atomic or molecular scale. It is defined as one twelfth of the rest mass of an unbound neutral atom of carbon-12 in its nuclear and electronic ground state, and has a value of...

) within 2–18 months depending on the material (resin, thickness, anti-oxidants, etc.) and the temperature and other factors in the environment.

OXO plastics will not degrade in a landfill environment due to insufficient oxygen present below a depth of approximately 15 cm. A PE plastic bag for example 30 µm thick with 2% prodegradant additive degrades within 3 months if left exposed in an open air environment in Thailand and a 150 µm thick PP container or sheet will degrade within 3–6 months.

Oxo treated products do not degrade rapidly because they are stabilized to control the service-life of the product. They will nevertheless degrade more quickly than nature's wastes such as twigs and straw (c10 years) and much more quickly than ordinary plastic (many decades).

Standards applicability

OXO plastic degrades in presence of UV and heat and can be recycled with normal plastic http://www.biodeg.org/position-papers/recycling/?domain=biodeg.orgIt is not compostable in industrial composting facilities according to the norm ASTM D6400.

This oxidation process takes longer than the 180 day period required by ASTM D6400 and similar standards for compostable plastics such as EN13432 and ISO 17088. This short time is necessary for compostable plastics because industrial composting has a short timescale, and is not the same as degradation in the environment. A leaf is generally considered to be biodegradable but it will not pass the composting standard due to the 180 day limit in ASTM D6400.

There is a Standard Guide (ASTM D6954-04) available which specifies procedures to test the degradability and to which some OXO complies. The ASTM Standard Guide is a 2-tier test procedure to determine whether a plastic could be marketed as "biodegradable". The Standard Guide references ASTM D5510 Test Specification which determines the usable life of the OXO plastic through Thermal Degradation. Secondly it also references ASTM D5208 which is used to determine the usable life based on UV degradation. These two test procedure in combination make up the 1-tier of the testing process for verifying a OXO plastic is degradable. After the 1-tier of testing is complete and the OXO plastic has been shown to be significantly degraded (usually done by FT-IR to show the new spectra peak at around the 1730 wavelength) the testing can move on to the 2-tier procedure. The ASTM Standards used for 2-tier testing are either ASTM D5338 or ASTM D5526. The specifications are both testing for the conversion of carbon in the polymer to CO2 in a control environment. After 60% carbon is converted from the sample the OXO plastic is said to have biodegraded. Although ASTM D6954-04 is only a Standard guide as opposed to a Standard Specification it does provide pass / fail criteria and therefore is useful in deciding whether a plastic could be marketed as "biodegradable". ASTM D6400 is a Standard Specification, but is appropriate only for compostable plastics. There is no need to refer to a Standard Specification unless a specific disposal route (e.g.: composting), is envisaged.