Manifold (scuba)

Encyclopedia

Scuba diving

Scuba diving is a form of underwater diving in which a diver uses a scuba set to breathe underwater....

a manifold is used to connect two diving cylinder

Diving cylinder

A diving cylinder, scuba tank or diving tank is a gas cylinder used to store and transport high pressure breathing gas as a component of a scuba set. It provides gas to the scuba diver through the demand valve of a diving regulator....

s (tanks) with breathing gas

Breathing gas

Breathing gas is a mixture of gaseous chemical elements and compounds used for respiration.Air is the most common and only natural breathing gas...

, providing a greater amount of gas for longer dive times and greater safety due to redundancy. Diving with two or more cylinders is associated with technical diving

Technical diving

Technical diving is a form of scuba diving that exceeds the scope of recreational diving...

.

Function

Longer and deeper dives require a greater amount of breathing gas, in turn requiring either a larger cylinder or multiple cylinders. A large tank (up to 18 LLitre

pic|200px|right|thumb|One litre is equivalent to this cubeEach side is 10 cm1 litre water = 1 kilogram water The litre is a metric system unit of volume equal to 1 cubic decimetre , to 1,000 cubic centimetres , and to 1/1,000 cubic metre...

) is very heavy and tends to raise the diver's center of mass

Center of mass

In physics, the center of mass or barycenter of a system is the average location of all of its mass. In the case of a rigid body, the position of the center of mass is fixed in relation to the body...

, making them unbalanced in water. A simple multiple-tank configuration called separate doubles consists of two mechanically attached but otherwise unconnected tanks with two complete regulator

Diving regulator

A diving regulator is a pressure regulator used in scuba or surface supplied diving equipment that reduces pressurized breathing gas to ambient pressure and delivers it to the diver. The gas may be air or one of a variety of specially blended breathing gases...

sets (with a total of two first stage regulators and two second stage regulators).

The function of a manifold is to connect the air supplies of two cylinders (called doubles or Twins), allowing the diver to breathe simultaneously from both. The manifold is a metal tube (usually made of aircraft grade brass

Brass

Brass is an alloy of copper and zinc; the proportions of zinc and copper can be varied to create a range of brasses with varying properties.In comparison, bronze is principally an alloy of copper and tin...

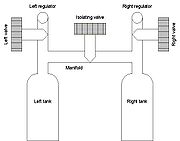

http://www.omsdive.com/valves.html) with two cylinder connectors, two first-stage regulator connectors and three valves, as shown in the figure above. The left and the right valves allow to disconnect the corresponding first stage regulators, leaving the entire gas supply to be used through the remaining regulator. The central valve, called the isolating valve, separates the tanks into two independent systems, each with its own first-stage and second-stage regulators.

Common emergency procedures

| This article is not a diving manual! See Wikipedia:Risk disclaimer. |

This section describes the standard procedures of addressing the out-of-air situation and the free-flow, an uncontrollable loss of breathing gas due to a mechanical malfunction of a regulator or a tank connection. The common technical diving configuration is assumed as defined by DIR.

Gas sharing

The diver breathes from the primary second-stage regulator connected to the right-shoulder cylinder by a long (2 meter/7-foot) hose. A secondary second-stage regulator is worn on his neck, connected to the left-shoulder cylinder by a short (0.5 meter/2-foot) hose. If a partner experiences an out-of-air emergency, diver hands him his primary regulator, which he knows for sure is functioning properly. The diver then switches to his secondary regulator. The entire gas supply is available to the two divers for the remainder of the dive.Primary regulator free-flow malfunction

If the primary regulator malfunctions, the diver closes the right-shoulder cylinder valve and switches to the secondary regulator. The entire gas supply is available for the remainder of the dive.Secondary second stage free-flow malfunction

If the secondary regulator malfunctions, the diver closes the left-shoulder cylinder valve, continuing to breathe through the primary regulator. The entire gas supply is available for the remainder of the dive.Right cylinder connection free-flow malfunction

Cylinder to manifold connection malfunction, though rare, can result in an extremely violent gas loss. In case of the right shoulder connection free-flow, the diver closes the isolating valve and the right shoulder cylinder valve. He then switches to the secondary regulator. Closing the right shoulder valve does not conserve the remaining gas in the right cylinder, but rather reduces the distraction and loss of visibility due to bubble flow. A half of the remaining gas volume is available for the remainder of the dive.Left cylinder connection free-flow malfunction

In case of the left shoulder connection free-flow, the diver closes the isolating valve and the left shoulder cylinder valve. He continues to breathe through the primary regulator. A half of the remaining gas volume is available for the remainder of the dive.Advantages

Compared to the alternatives, the manifold offers the following advantages:- Convenience - offers a better fit of cylinders than a single large tank, improving streamlining and comfort of the diver.

- Simplicity - the ability to breathe through an entire dive from a single regulator without the need to change second stages, except in an emergency.

- Ease of air sharing - a standard procedure exists for the situation when air sharing is needed. The long hose regulator is passed to the partner while the air donor switches to the short hose.

- Standard malfunction treatment - in case of a regulator or manifold malfunction a standard procedure can be used to minimize the gas loss. The diver can localize the malfunction and isolate it from the functioning system by closing the necessary valves.

Criticism

A manifold is a single point of failureSingle point of failure

A single point of failure is a part of a system that, if it fails, will stop the entire system from working. They are undesirable in any system with a goal of high availability or reliability, be it a business practice, software application, or other industrial system.-Overview:Systems can be made...

for the gas supply, especially dangerous in overhead environments such as caves

Cave diving

Cave diving is a type of technical diving in which specialized equipment is used to enable the exploration of caves which are at least partially filled with water. In the United Kingdom it is an extension of the more common sport of caving, and in the United States an extension of the more common...

or wrecks

Wreck diving

Wreck diving is a type of recreational diving where shipwrecks are explored. Although most wreck dive sites are at shipwrecks, there is an increasing trend to scuttle retired ships to create artificial reef sites...

.