Inverythan rail accident

Encyclopedia

Auchterless

Auchterless is a village in Aberdeenshire, Scotland. The nearest large settlement is Turriff. It is traditionally known as "Kirkton of Auchterless".-History:...

and Fyvie

Fyvie

Fyvie is a village in the Formartine area of Aberdeenshire, Scotland.-Fyvie Castle:Fyvie Castle is reputed to have been built by King William the Lyon in the early thirteenth century...

. The engine of the freight/passenger train (5 loaded wagons, 4 carriages) crossed safely, but most of the train fell into the gap onto a road below.

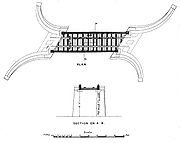

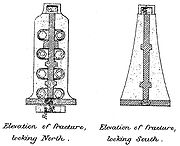

Cause

A simple vertical crack with a freshly fractured surface and old rust marks on the face was easily distinguished to the side of the centre joint, extending from the bottom flange to the top of the girder. This was associated with a casting defectCasting defect

A casting defect is an irregularity in the metal casting process that is undesired. Some defects can be tolerated while others can be repaired otherwise they must be eliminated...

hidden behind a suface skin of sound metal at the thickest part of the section where the flanges met the web. This was described by the accident report as

a large honeycomb, or drawhole, which measured 3½ ins (c 90 mm) across at the face, and narrowed to about l½ ins (c 40 mm). inside , 2⅜ ins (c 60 mm) in extreme depth and 6ins (c 150 mm). in extreme length, extending inwards and downwards ...but not within 1 ½ ins of the outer face of the joint flange. The total capacity of the hole, measured by filling it with water, was 15 ½ cubic inches (about 250 ml) and, as the metal immediately round the hole was not sound, this amount does not measure the actual extent of the flaw.

There were other signs of poor foundry practice when the girder had been cast; honeycombing elsewhere, a cold shut (incomplete fusion between different streams of filling metal), and residual stress

Residual stress

Residual stresses are stresses that remain after the original cause of the stresses has been removed. They remain along a cross section of the component, even without the external cause. Residual stresses occur for a variety of reasons, including inelastic deformations and heat treatment...

es in the girder web (as a consequence of which, when sample cores were being drilled for testing, the web (but not the flanges) fractured along the line of holes. Whilst the metal appeared to be of good quality to the naked eye, the tested tensile strength

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

of the metal varied widely from the lowest of ~4.5 tsi (c 70 MPa) (close to the honeycombing) with a mean of 7.5 tsi (c 115 MPa).

The actual strength fell below this because of the casting defect; "The sectional area of the bottom flange would at one place be reduced from 36 (sq) ins to only 28 (sq) ins, thus enormously reducing the strength of the girder"

It was considered that the fault could not have been detected by routine inspections, so no blame attached to those responsible for inspecting the bridge, but this conclusion gave the BoT inspector considerable concern

For, if one such girder, which was of sufficient theoretical strength when cast, and which, being in constant use for 25 years, had never shown any signs of weakness or any outward flaw, suddenly breaks down, owing to a defect which must have existed when it was originally made, and laid latent ever since, it is very difficult to know what steps should be taken to guard against the recurrence of a like disaster.

Aftermath

The railway's 8 bridges with similar double structure were replaced as quickly as possible, and a warning was circulated to all British railways with similar cast iron under-bridges. Little further action was taken until the 1891 Norwood Junction rail accidentNorwood Junction rail accident

The Norwood Junction railway crash occurred on 1 May 1891, when a cast iron under-bridge some 60 yards north east of Norwood Junction railway station fractured under an express train from Brighton to London in southern England....

of a first class train which injured 1 businessman because of a cast iron girder fracture from a latent defect

Latent defect

In the law of the sale of property a latent defect is a fault in the property that could not have been discovered by a reasonably thorough inspection before the sale....

.