Integrated Gasification Combined Cycle

Encyclopedia

An integrated gasification combined cycle (IGCC) is a technology that turns coal

into gas—synthesis gas (syngas

). It then removes impurities from the coal gas before it is combusted and attempts to turn any pollutants into re-usable byproducts. This results in lower emissions of sulfur dioxide

, particulates, and mercury

. Excess heat from the primary combustion and generation is then passed to a steam cycle, similarly to a combined cycle gas turbine. This then also results in improved efficiency compared to conventional pulverized coal.

The gasification process can produce syngas

The gasification process can produce syngas

from high-sulfur coal, heavy petroleum residues and biomass

.

The plant is called integrated because its syngas is produced in a gasification

unit in the plant which has been optimized for the plant's combined cycle.

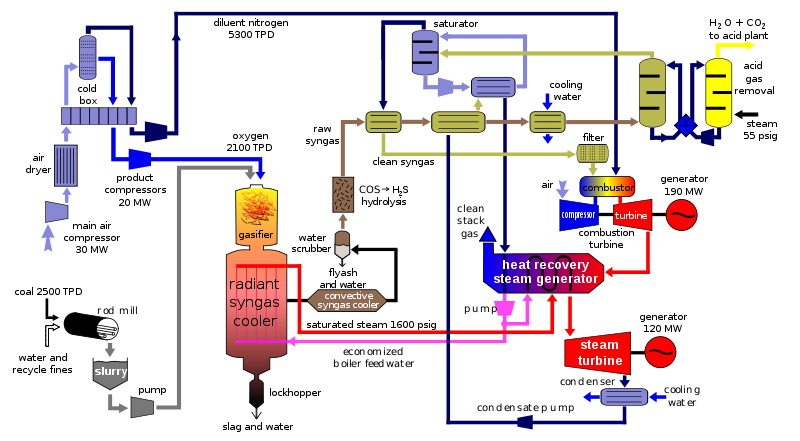

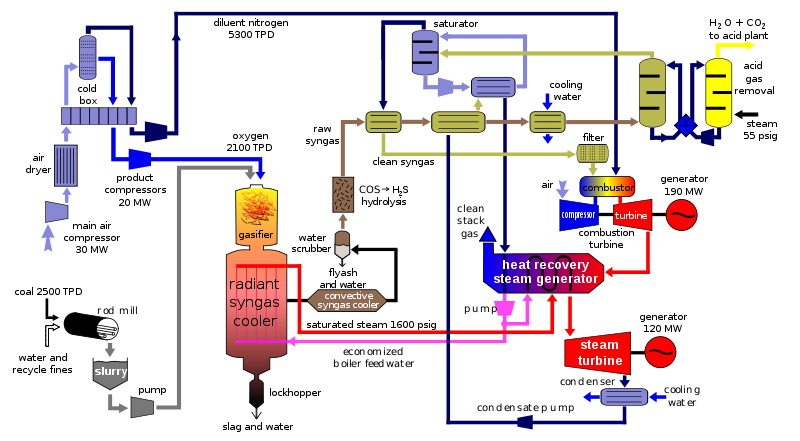

In this example the syngas produced is used as fuel in a gas turbine which produces electrical power. To improve the overall process efficiency heat is recovered from both the gasification process and also the gas turbine exhaust in 'Waste Heat Boilers' producing steam. This steam is then used in steam turbines to produce additional electrical power.

, Polk Power Station in Tampa, Florida

(online 1996), and Pinon Pine in Reno, Nevada

. In the Reno demonstration project, researchers found that then-current IGCC technology would not work more than 300 feet (100m) above sea level. The DOE report in reference 3 however makes no mention of any altitude effect, and most of the problems were associated with the solid waste extraction system. The plant failed.

Poland's Kędzierzyn will soon host a Zero-Emission Power & Chemical Plant

that combines coal gasification technology with Carbon Capture & Storage

(CCS). The supplement of up to 10% biomass in the combustion process will make this plant even more environmentally-friendly.

The first generation of IGCC plants polluted less than contemporary coal-based technology, but also polluted water; for example, the Wabash River Plant was out of compliance with its water permit during 1998–2001

because it emitted arsenic, selenium and cyanide. The Wabash River Generating Station is now wholly owned and operated by the Wabash River Power Association.

IGCC is now touted as capture ready and could potentially capture and store carbon dioxide. (See FutureGen

)

There are several advantages and disadvantages when compared to conventional post combustion carbon capture and various variations and these are fully discussed at reference 6.

Outdated per megawatt-hour cost of an IGCC plant vs a pulverized coal plant coming online in 2010 would be $56 vs $52, and it is claimed that IGCC becomes even more attractive when you include the costs of carbon capture and sequestration, IGCC becoming $79 per megawatt-hour vs. $95 per megawatt-hour for pulverized coal. Recent testimony in regulatory proceedings show the cost of IGCC to be twice that predicted by Goddell, from $96 to 104/MWhr. That's before addition of carbon capture and sequestration (sequestration has been a mature technology

at both Weyburn in the US (for enhanced oil recovery) and Sleipner in the North Sea at a commercial scale for the past ten years)—capture at a 90% rate is expected to have a $30/MWh additional cost.

Wabash River was down repeatedly for long stretches due to gasifier problems. The gasifier problems have not been remedied—subsequent projects, such as Excelsior's Mesaba Project, have a third gasifier and train built in. However, the past year has seen Wabash River running reliably, with availability comparable to or better than other technologies.

The Polk County IGCC has design problems. First, the project was initially shut down because of corrosion in the slurry pipeline that fed slurried coal from the rail cars into the gasifier. A new coating for the pipe was developed. Second, the thermocoupler was replaced in less than two years; an indication that the gasifier had problems with a variety of feedstocks; from bituminous to sub-bituminous coal. The gasifier was designed to also handle lower rank lignites. Third, unplanned down time on the gasifier because of refractory liner problems, and those problems were expensive to repair. The gasifier was originally designed in Italy to be half the size of what was built at Polk. Newer ceramic materials may assist in improving gasifier performance and longevity. Understanding the operating problems of the current IGCC plant is necessary to improve the design for the IGCC plant of the future. (Polk IGCC Power Plant, http://www.clean-energy.us/projects/polk_florida.html.) Keim, K., 2009, IGCC A Project on Sustainability Management Systmes for Plant Re-Design and Re-Image. This is an unpublished paper from Harvard University)

General Electric is currently designing an IGCC model plant that should introduce greater reliability. GE's model features advanced turbines optimized for the coal syngas. Eastman's industrial gasification plant in Kingsport, TN uses a GE Energy solid-fed gasifier. Eastman, a fortune 500 company, built the facility in 1983 without any state or federal subsidies and turns a profit.

There are several refinery-based IGCC plants in Europe that have demonstrated good availability (90-95%) after initial shakedown periods. Several factors help this performance:

Another IGCC success story has been the 250 MW Buggenum plant in The Netherlands. It also has good availability. This coal-based IGCC plant currently uses about 30% biomass as a supplemental feedstock. The owner, NUON, is paid an incentive fee by the government to use the biomass. NUON is constructing a 1,300 MW IGCC plant in the Netherlands. The Nuon Magnum IGCC power plant will be commissioned in 2011. Mitsubishi Heavy Industries has been awarded to construct the power plant.

A new generation of IGCC-based coal-fired power plants has been proposed, although none is yet under construction. Projects are being developed by AEP

, Duke Energy

, and Southern Company

in the US, and in Europe by ZAK/PKE

, Centrica

(UK), E.ON

and RWE (both Germany) and NUON (Netherlands). In Minnesota, the state's Dept. of Commerce analysis found IGCC to have the highest cost, with an emissions profile not significantly better than pulverized coal. In Delaware, the Delmarva and state consultant analysis had essentially the same results.

The high cost of IGCC is the biggest obstacle to its integration in the power market; however, most energy executives recognize that carbon regulation is coming soon. Bills requiring carbon reduction are being proposed again both the House and the Senate, and with the Democratic majority it seems likely that with the next President there will be a greater push for carbon regulation. The Supreme Court decision requiring the EPA to regulate carbon (Commonwealth of Massachusetts et al. v. Environmental Protection Agency et al.)

also speaks to the likelihood of future carbon regulations coming sooner, rather than later. With carbon capture, the cost of electricity from an IGCC plant would increase approximately 30%. For a natural gas CC, the increase is approximately 33%. For a pulverized coal plant, the increase is approximately 68%. This potential for less expensive carbon capture makes IGCC an attractive choice for keeping low cost coal an available fuel source in a carbon constrained world.

In Japan, electric power companies, in conjunction with Mitsubishi Heavy Industries

has been operating a 200 t/d IGCC pilot plant since the early '90s. In September 2007, they started up a 250 MW demo plant in Nakoso. It runs on air-blown (not oxygen) dry feed coal only. It burns PRB coal with an unburned carbon content ratio of <0.1% and no detected leaching of trace elements. It employs not only F type turbines but G type as well. (see gasification.org link below)

Next generation IGCC plants with CO2 capture technology will be expected to have higher thermal efficiency and to hold the cost down because of simplified systems compared to conventional IGCC. The main feature is that instead of using oxygen and nitrogen to gasify coal, they use oxygen and CO2. The main advantage is that it is possible to improve the performance of cold gas efficiency and to reduce the unburned carbon (char).

With a 1300 degrees C class gas turbine it is possible to achieve 42% net thermal efficiency, rising to 45% with a 1500 degree class gas turbine, with CO2 capture. In case of conventional IGCC systems, it is only possible to achieve just over 30% efficiency with a 1300 degree gas turbine.

The CO2 extracted from gas turbine exhaust gas is utilized in this system. Using a closed gas turbine system capable of capturing the CO2 by direct compression and liquefication obviates the need for a separation and capture system.

Senator Harry Reid

(Majority Leader of the 2007/2008 U.S. Senate) told the 2007 Clean Energy Summit that he will do everything he can to stop construction of proposed new IGCC coal-fired electric power plants in Nevada. Reid wants Nevada utility companies to invest in solar energy, wind energy

and geothermal energy instead of coal technologies. Reid stated that global warming

is a reality, and just one proposed coal-fired plant would contribute to it by burning seven million tons of coal a year. The long-term healthcare costs would be far too high, he claimed (no source attributed). "I'm going to do everything I can to stop these plants.", he said. "There is no clean coal technology

. There is cleaner coal technology, but there is no clean coal technology."

One of the most efficient ways to treat the H2S gas from a IGCC plant, is by converting it into sulphuric acid in a wet gas sulphuric acid process wsa process

However, the majority of the H2S treating plants utilize the modified Claus process, as the sulphur market infrastructure and the transportation costs of sulphuric acid versus sulphur are in favour of sulphur production.

Coal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

into gas—synthesis gas (syngas

Syngas

Syngas is the name given to a gas mixture that contains varying amounts of carbon monoxide and hydrogen. Examples of production methods include steam reforming of natural gas or liquid hydrocarbons to produce hydrogen, the gasification of coal, biomass, and in some types of waste-to-energy...

). It then removes impurities from the coal gas before it is combusted and attempts to turn any pollutants into re-usable byproducts. This results in lower emissions of sulfur dioxide

Sulfur dioxide

Sulfur dioxide is the chemical compound with the formula . It is released by volcanoes and in various industrial processes. Since coal and petroleum often contain sulfur compounds, their combustion generates sulfur dioxide unless the sulfur compounds are removed before burning the fuel...

, particulates, and mercury

Mercury (element)

Mercury is a chemical element with the symbol Hg and atomic number 80. It is also known as quicksilver or hydrargyrum...

. Excess heat from the primary combustion and generation is then passed to a steam cycle, similarly to a combined cycle gas turbine. This then also results in improved efficiency compared to conventional pulverized coal.

Significance

Coal can be found in abundance in America and many other countries and its price has remained relatively constant in recent years. Consequently it is used for about 50 percent of U.S. electricity needs. Thus the lower emissions that IGCC technology allows may be important in the future as emission regulations tighten due to growing concern for the impacts of pollutants on the environment and the globe.Operations

Below is a schematic flow diagram of an IGCC plant:

Syngas

Syngas is the name given to a gas mixture that contains varying amounts of carbon monoxide and hydrogen. Examples of production methods include steam reforming of natural gas or liquid hydrocarbons to produce hydrogen, the gasification of coal, biomass, and in some types of waste-to-energy...

from high-sulfur coal, heavy petroleum residues and biomass

Biomass

Biomass, as a renewable energy source, is biological material from living, or recently living organisms. As an energy source, biomass can either be used directly, or converted into other energy products such as biofuel....

.

The plant is called integrated because its syngas is produced in a gasification

Gasification

Gasification is a process that converts organic or fossil based carbonaceous materials into carbon monoxide, hydrogen, carbon dioxide and methane. This is achieved by reacting the material at high temperatures , without combustion, with a controlled amount of oxygen and/or steam...

unit in the plant which has been optimized for the plant's combined cycle.

In this example the syngas produced is used as fuel in a gas turbine which produces electrical power. To improve the overall process efficiency heat is recovered from both the gasification process and also the gas turbine exhaust in 'Waste Heat Boilers' producing steam. This steam is then used in steam turbines to produce additional electrical power.

Installations

In 2007 there were only two IGCC plants generating power in the U.S.; however, several new IGCC plants are expected to come online in the U.S. in the 2012-2020 time frame. The DOE Clean Coal Demonstration Project helped construct 3 IGCC plants: Wabash River Power Station in West Terre Haute, IndianaWest Terre Haute, Indiana

West Terre Haute is a town in Sugar Creek Township, Vigo County, Indiana, on the western side of the Wabash River near Terre Haute. The population was 2,236 at the 2010 census...

, Polk Power Station in Tampa, Florida

Tampa, Florida

Tampa is a city in the U.S. state of Florida. It serves as the county seat for Hillsborough County. Tampa is located on the west coast of Florida. The population of Tampa in 2010 was 335,709....

(online 1996), and Pinon Pine in Reno, Nevada

Reno, Nevada

Reno is the county seat of Washoe County, Nevada, United States. The city has a population of about 220,500 and is the most populous Nevada city outside of the Las Vegas metropolitan area...

. In the Reno demonstration project, researchers found that then-current IGCC technology would not work more than 300 feet (100m) above sea level. The DOE report in reference 3 however makes no mention of any altitude effect, and most of the problems were associated with the solid waste extraction system. The plant failed.

Poland's Kędzierzyn will soon host a Zero-Emission Power & Chemical Plant

Kedzierzyn Zero-Emission Plant

The Kędzierzyn Zero-Emission Power and Chemical Complex is a proposed facility in Kędzierzyn-Koźle, Poland. It will combine power and heat generation with that of chemical products and carbon capture and storage. The project is proposed by a consortium of chemicals producer Zakłady Azotowe...

that combines coal gasification technology with Carbon Capture & Storage

Carbon capture and storage

Carbon capture and storage , alternatively referred to as carbon capture and sequestration, is a technology to prevent large quantities of from being released into the atmosphere from the use of fossil fuel in power generation and other industries. It is often regarded as a means of mitigating...

(CCS). The supplement of up to 10% biomass in the combustion process will make this plant even more environmentally-friendly.

The first generation of IGCC plants polluted less than contemporary coal-based technology, but also polluted water; for example, the Wabash River Plant was out of compliance with its water permit during 1998–2001

because it emitted arsenic, selenium and cyanide. The Wabash River Generating Station is now wholly owned and operated by the Wabash River Power Association.

IGCC is now touted as capture ready and could potentially capture and store carbon dioxide. (See FutureGen

FutureGen

FutureGen is a US government project announced by President George W. Bush in 2003; its initial plan involved the construction of a near zero-emissions coal-fueled power plant to produce hydrogen and electricity while using carbon capture and storage....

)

There are several advantages and disadvantages when compared to conventional post combustion carbon capture and various variations and these are fully discussed at reference 6.

Cost and reliability

The main problem for IGCC is its extremely high capital cost, upwards of $3,593/kW. Official US government figures give more optimistic estimates of $1,491/kW installed capacity (2005 dollars) v. $1,290 for a conventional clean coal facility, but in light of current applications, these cost estimates have been demonstrated to be incorrect.Outdated per megawatt-hour cost of an IGCC plant vs a pulverized coal plant coming online in 2010 would be $56 vs $52, and it is claimed that IGCC becomes even more attractive when you include the costs of carbon capture and sequestration, IGCC becoming $79 per megawatt-hour vs. $95 per megawatt-hour for pulverized coal. Recent testimony in regulatory proceedings show the cost of IGCC to be twice that predicted by Goddell, from $96 to 104/MWhr. That's before addition of carbon capture and sequestration (sequestration has been a mature technology

Mature technology

A mature technology is a technology that has been in use for long enough that most of its initial faults and inherent problems have been removed or reduced by further development...

at both Weyburn in the US (for enhanced oil recovery) and Sleipner in the North Sea at a commercial scale for the past ten years)—capture at a 90% rate is expected to have a $30/MWh additional cost.

Wabash River was down repeatedly for long stretches due to gasifier problems. The gasifier problems have not been remedied—subsequent projects, such as Excelsior's Mesaba Project, have a third gasifier and train built in. However, the past year has seen Wabash River running reliably, with availability comparable to or better than other technologies.

The Polk County IGCC has design problems. First, the project was initially shut down because of corrosion in the slurry pipeline that fed slurried coal from the rail cars into the gasifier. A new coating for the pipe was developed. Second, the thermocoupler was replaced in less than two years; an indication that the gasifier had problems with a variety of feedstocks; from bituminous to sub-bituminous coal. The gasifier was designed to also handle lower rank lignites. Third, unplanned down time on the gasifier because of refractory liner problems, and those problems were expensive to repair. The gasifier was originally designed in Italy to be half the size of what was built at Polk. Newer ceramic materials may assist in improving gasifier performance and longevity. Understanding the operating problems of the current IGCC plant is necessary to improve the design for the IGCC plant of the future. (Polk IGCC Power Plant, http://www.clean-energy.us/projects/polk_florida.html.) Keim, K., 2009, IGCC A Project on Sustainability Management Systmes for Plant Re-Design and Re-Image. This is an unpublished paper from Harvard University)

General Electric is currently designing an IGCC model plant that should introduce greater reliability. GE's model features advanced turbines optimized for the coal syngas. Eastman's industrial gasification plant in Kingsport, TN uses a GE Energy solid-fed gasifier. Eastman, a fortune 500 company, built the facility in 1983 without any state or federal subsidies and turns a profit.

There are several refinery-based IGCC plants in Europe that have demonstrated good availability (90-95%) after initial shakedown periods. Several factors help this performance:

- None of these facilities use advanced technology (F type) gas turbines.

- All refinery-based plants use refinery residues, rather than coal, as the feedstock. This eliminates coal handling and coal preparation equipment and its problems. Also, there is a much lower level of ash produced in the gasifier, which reduces cleanup and downtime in its gas cooling and cleaning stages.

- These non-utility plants have recognized the need to treat the gasification system as an up-front chemical processing plant, and have reorganized their operating staff accordingly.

Another IGCC success story has been the 250 MW Buggenum plant in The Netherlands. It also has good availability. This coal-based IGCC plant currently uses about 30% biomass as a supplemental feedstock. The owner, NUON, is paid an incentive fee by the government to use the biomass. NUON is constructing a 1,300 MW IGCC plant in the Netherlands. The Nuon Magnum IGCC power plant will be commissioned in 2011. Mitsubishi Heavy Industries has been awarded to construct the power plant.

A new generation of IGCC-based coal-fired power plants has been proposed, although none is yet under construction. Projects are being developed by AEP

American Electric Power

American Electric Power is a major investor-owner electric utility in various parts of the United States. AEP ranks among the nation's largest generators of electricity, owning nearly 38,000 megawatts of generating capacity in the U.S...

, Duke Energy

Duke Energy

Duke Energy , headquartered in Charlotte, North Carolina, is an energy company with assets in the United States, Canada and Latin America.-Overview:...

, and Southern Company

Southern Company

Southern Company is a public utility holding company of primarily electric utilities in the southern United States. It is headquartered in Atlanta, Georgia with executive offices also located in Birmingham, Alabama. The company is currently the 16th largest utility company in the world and the...

in the US, and in Europe by ZAK/PKE

Kedzierzyn Zero-Emission Plant

The Kędzierzyn Zero-Emission Power and Chemical Complex is a proposed facility in Kędzierzyn-Koźle, Poland. It will combine power and heat generation with that of chemical products and carbon capture and storage. The project is proposed by a consortium of chemicals producer Zakłady Azotowe...

, Centrica

Centrica

Centrica plc is a multinational utility company, based in the United Kingdom but also with interests in North America. Centrica is the largest supplier of gas to domestic customers in the UK, and one of the largest suppliers of electricity, operating under the trading names "Scottish Gas" in...

(UK), E.ON

E.ON

E.ON AG, marketed with an interpunct as E•ON, is the holding company of the world's largest investor-owned energy service provider based in Düsseldorf, Germany. The name comes from the Greek word aeon which means eternity....

and RWE (both Germany) and NUON (Netherlands). In Minnesota, the state's Dept. of Commerce analysis found IGCC to have the highest cost, with an emissions profile not significantly better than pulverized coal. In Delaware, the Delmarva and state consultant analysis had essentially the same results.

The high cost of IGCC is the biggest obstacle to its integration in the power market; however, most energy executives recognize that carbon regulation is coming soon. Bills requiring carbon reduction are being proposed again both the House and the Senate, and with the Democratic majority it seems likely that with the next President there will be a greater push for carbon regulation. The Supreme Court decision requiring the EPA to regulate carbon (Commonwealth of Massachusetts et al. v. Environmental Protection Agency et al.)

also speaks to the likelihood of future carbon regulations coming sooner, rather than later. With carbon capture, the cost of electricity from an IGCC plant would increase approximately 30%. For a natural gas CC, the increase is approximately 33%. For a pulverized coal plant, the increase is approximately 68%. This potential for less expensive carbon capture makes IGCC an attractive choice for keeping low cost coal an available fuel source in a carbon constrained world.

In Japan, electric power companies, in conjunction with Mitsubishi Heavy Industries

Mitsubishi Heavy Industries

, or MHI, is a Japanese company. It is one of the core companies of Mitsubishi Group.-History:In 1870 Yataro Iwasaki, the founder of Mitsubishi took a lease of Government-owned Nagasaki Shipyard. He named it Nagasaki Shipyard & Machinery Works, and started the shipbuilding business on a full scale...

has been operating a 200 t/d IGCC pilot plant since the early '90s. In September 2007, they started up a 250 MW demo plant in Nakoso. It runs on air-blown (not oxygen) dry feed coal only. It burns PRB coal with an unburned carbon content ratio of <0.1% and no detected leaching of trace elements. It employs not only F type turbines but G type as well. (see gasification.org link below)

Next generation IGCC plants with CO2 capture technology will be expected to have higher thermal efficiency and to hold the cost down because of simplified systems compared to conventional IGCC. The main feature is that instead of using oxygen and nitrogen to gasify coal, they use oxygen and CO2. The main advantage is that it is possible to improve the performance of cold gas efficiency and to reduce the unburned carbon (char).

With a 1300 degrees C class gas turbine it is possible to achieve 42% net thermal efficiency, rising to 45% with a 1500 degree class gas turbine, with CO2 capture. In case of conventional IGCC systems, it is only possible to achieve just over 30% efficiency with a 1300 degree gas turbine.

The CO2 extracted from gas turbine exhaust gas is utilized in this system. Using a closed gas turbine system capable of capturing the CO2 by direct compression and liquefication obviates the need for a separation and capture system.

IGCC Emission Controversy

In 2007, the New York State Attorney General's office demanded full disclosure of "financial risks from greenhouse gases" to the shareholders of electric power companies proposing the development of IGCC coal-fired power plants. "Any one of the several new or likely regulatory initiatives for CO2 emissions from power plants - including state carbon controls, EPA's regulations under the Clean Air Act, or the enactment of federal global warming legislation - would add a significant cost to carbon-intensive coal generation"; U.S. Senator Hillary Clinton from New York has proposed that this full risk disclosure be required of all publicly-traded power companies nationwide. This honest disclosure has begun to reduce investor interest in all types of existing-technology coal-fired power plant development, including IGCC.Senator Harry Reid

Harry Reid

Harry Mason Reid is the senior United States Senator from Nevada, serving since 1987. A member of the Democratic Party, he has been the Senate Majority Leader since January 2007, having previously served as Minority Leader and Minority and Majority Whip.Previously, Reid was a member of the U.S...

(Majority Leader of the 2007/2008 U.S. Senate) told the 2007 Clean Energy Summit that he will do everything he can to stop construction of proposed new IGCC coal-fired electric power plants in Nevada. Reid wants Nevada utility companies to invest in solar energy, wind energy

Wind energy

Wind energy is the kinetic energy of air in motion; see also wind power.Total wind energy flowing through an imaginary area A during the time t is:E = ½ m v2 = ½ v 2...

and geothermal energy instead of coal technologies. Reid stated that global warming

Global warming

Global warming refers to the rising average temperature of Earth's atmosphere and oceans and its projected continuation. In the last 100 years, Earth's average surface temperature increased by about with about two thirds of the increase occurring over just the last three decades...

is a reality, and just one proposed coal-fired plant would contribute to it by burning seven million tons of coal a year. The long-term healthcare costs would be far too high, he claimed (no source attributed). "I'm going to do everything I can to stop these plants.", he said. "There is no clean coal technology

Clean coal technology

Clean coal technology is a collection of technologies being developed to reduce the environmental impact of coal energy generation. When coal is used as a fuel source, the gaseous emmissions generated by the thermal decomposition of the coal, include sulphur dioxide, nitrogen dioxide, carbon...

. There is cleaner coal technology, but there is no clean coal technology."

One of the most efficient ways to treat the H2S gas from a IGCC plant, is by converting it into sulphuric acid in a wet gas sulphuric acid process wsa process

However, the majority of the H2S treating plants utilize the modified Claus process, as the sulphur market infrastructure and the transportation costs of sulphuric acid versus sulphur are in favour of sulphur production.

External links

- Hunstown: Ireland's most efficient power plant @ SiemensSiemens AGSiemens AG is a German multinational conglomerate company headquartered in Munich, Germany. It is the largest Europe-based electronics and electrical engineering company....

Power Generation website - Natural Gas Combined-cycle Gas Turbine Power Plants Northwest Power Planning Council, New Resource Characterization for the Fifth Power Plan, August 2002

- Combined cycle solar power