Injection pump

Encyclopedia

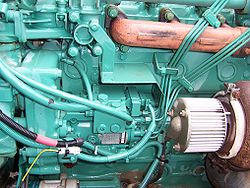

Diesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

or less typically, a gasoline engine. Traditionally, the pump is driven indirectly from the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

by gears, chains or a toothed belt (often the timing belt

Timing belt

A timing belt, or cam belt , is a part of an internal combustion engine that controls the timing of the engine's valves. Some engines, such as the flat-4 Volkswagen air-cooled engine, and the straight-6 Toyota F engine use timing gears...

) that also drives the camshaft

Camshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

on overhead-cam engines ( OHC ). It rotates at half crankshaft speed in a conventional four-stroke engine. Its timing is such that the fuel is injected only very slightly before top dead centre of that cylinder's compression stroke. It is also common for the pump belt on gasoline engines to be driven directly from the camshaft. In some systems injection pressures can be as high as 200Mpa.

Safety

Because of the need for positive injection into a very high-pressurePressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

environment, the pump develops great pressure—typically 15,000 psi (100 MPa) or more on newer systems. This is a good reason to take great care when working on diesel systems; escaping fuel at this sort of pressure can easily penetrate skin and clothes, and be injected into body tissues with medical consequences serious enough to warrant amputation

Amputation

Amputation is the removal of a body extremity by trauma, prolonged constriction, or surgery. As a surgical measure, it is used to control pain or a disease process in the affected limb, such as malignancy or gangrene. In some cases, it is carried out on individuals as a preventative surgery for...

.

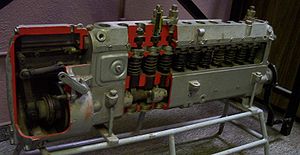

Construction

Helix

A helix is a type of smooth space curve, i.e. a curve in three-dimensional space. It has the property that the tangent line at any point makes a constant angle with a fixed line called the axis. Examples of helixes are coil springs and the handrails of spiral staircases. A "filled-in" helix – for...

slot in the cylinder. When all the cylinders are rotated at once, they simultaneously vary their injection volume to produce more or less power from the engine. Inline pumps still find favour on large multi-cylinder engines such as those on trucks, construction plant, static engines and agricultural vehicles.

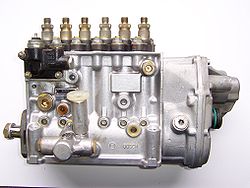

Robert Bosch GmbH

Robert Bosch GmbH is a multinational engineering and electronics company headquartered in Gerlingen, near Stuttgart, Germany. It is the world's largest supplier of automotive components...

VE pump vary the injection timing with crank speed to allow greater power at high crank speeds, and smoother, more economical running at slower revs. Some VE variants have a pressure-based system that allows the injection volume to increase over normal to allow a turbocharger

Turbocharger

A turbocharger, or turbo , from the Greek "τύρβη" is a centrifugal compressor powered by a turbine that is driven by an engine's exhaust gases. Its benefit lies with the compressor increasing the mass of air entering the engine , thereby resulting in greater performance...

or supercharger

Supercharger

A supercharger is an air compressor used for forced induction of an internal combustion engine.The greater mass flow-rate provides more oxygen to support combustion than would be available in a naturally aspirated engine, which allows more fuel to be burned and more work to be done per cycle,...

equipped engine to develop more power under boost conditions.

Governor (device)

A governor, or speed limiter, is a device used to measure and regulate the speed of a machine, such as an engine. A classic example is the centrifugal governor, also known as the Watt or fly-ball governor, which uses a rotating assembly of weights mounted on arms to determine how fast the engine...

to cut fuel supply if the crank speed endangers the engine - the heavy moving parts of diesel engines do not tolerate overspeeding well, and catastrophic damage can occur if they are over-revved.

New types

Mechanical pumps are gradually being phased out in order to comply with international emissions directives, and to increase performance and economy. Alternatives include common rail diesel systems and electronic unit direct injectionUnit Injector

Unit Injector is an integrated direct fuel injection system for diesel engines, combining the injector nozzle and the injection pump in a single component...

systems. These allow for higher pressures to be developed, and for much finer control of injection volumes compared to mechanical systems.