Hot blast

Encyclopedia

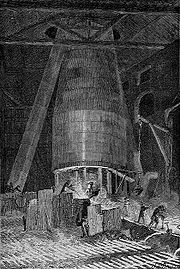

Air preheater

An air preheater is a general term to describe any device designed to heat air before another process with the primary objective of increasing the thermal efficiency of the process...

blown into a blast furnace

Blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron.In a blast furnace, fuel and ore and flux are continuously supplied through the top of the furnace, while air is blown into the bottom of the chamber, so that the chemical reactions...

or other metallurgical process. This has the result of considerably reducing the fuel

Fuel

Fuel is any material that stores energy that can later be extracted to perform mechanical work in a controlled manner. Most fuels used by humans undergo combustion, a redox reaction in which a combustible substance releases energy after it ignites and reacts with the oxygen in the air...

consumed in the process. This was invented and patented for iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

furnaces by James Beaumont Neilson in 1828 at Wilsontown Ironworks

Wilsontown Ironworks

The ruins of the Wilsontown Ironworks are located near the village of Forth in Scotland, approximately to the south east of Glasgow. The works were founded by the three Wilson brothers in 1779, and operated until 1842. The works had two blast furnaces, and in 1790 a forge was added. Later a...

in Scotland, but was later applied in other contexts, including late bloomeries

Bloomery

A bloomery is a type of furnace once widely used for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. A bloomery's product is a porous mass of iron and slag called a bloom. This mix of slag and iron in the bloom is termed sponge iron, which...

.

The invention of the hot blast process was of particular importance to the iron industry in the United States. At the time the process was invented, good coking

Coke (fuel)

Coke is the solid carbonaceous material derived from destructive distillation of low-ash, low-sulfur bituminous coal. Cokes from coal are grey, hard, and porous. While coke can be formed naturally, the commonly used form is man-made.- History :...

coal

Coal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

was not yet being mined in the U.S., and iron furnaces were compelled to use charcoal

Charcoal

Charcoal is the dark grey residue consisting of carbon, and any remaining ash, obtained by removing water and other volatile constituents from animal and vegetation substances. Charcoal is usually produced by slow pyrolysis, the heating of wood or other substances in the absence of oxygen...

. This meant that any given iron furnace required vast tracts of forested land for charcoal production, and generally went out of blast when the nearby woods had been felled. Attempts to use anthracite as a fuel had all ended in failure, as the coal resisted ignition under cold blast conditions. In 1831, Dr. Frederick W. Gessenhainer filed for a U.S. patent on the use of hot blast and anthracite to smelt iron. He produced a small quantity of anthracite iron

Anthracite iron

Anthracite iron is the substance created by the smelting together of anthracite coal and iron ore.-Development of the process:Research into the smelting of iron using anthracite coal began in the 1820s...

by this method at Valley Furnace near Pottsville

Pottsville, Pennsylvania

Pottsville is the only city in and the county seat of Schuylkill County, Pennsylvania, United States. The population was 15,549 at the 2000 census. The city lies along the west bank of the Schuylkill River, north-west of Philadelphia...

in 1836, but due to breakdowns and his illness and death in 1838, he was not able to carry the process into large-scale production. Indendependently, George Crane and David Thomas

David Thomas (industrialist)

David Thomas was a native of Wales who was influential in the birth of the Industrial Revolution in the US.-Development of the hot blast:David Thomas was born in Cadoxton, near Neath...

, of the Yniscedwyn Works in Wales

Wales

Wales is a country that is part of the United Kingdom and the island of Great Britain, bordered by England to its east and the Atlantic Ocean and Irish Sea to its west. It has a population of three million, and a total area of 20,779 km²...

, conceived of the same idea, and Crane filed for a British patent in 1836. They began producing iron by the new process on February 5, 1837. Crane subsequently bought Gessenhainer's patent and patented additions to it, controlling the use of the process in both Britain and the U.S. While Crane remained in Wales, Thomas would move to the U.S. on behalf of the Lehigh Coal and Navigation Company

Lehigh Coal and Navigation Company

The Lehigh Coal and Navigation Company is an anthracite coal mining company headquartered in Pottsville, Schuylkill County, Pennsylvania, U.S.A., with operations in the areas of Tamaqua, Coaldale, and Lansford...

and found the Lehigh Crane Iron Company

Lehigh Crane Iron Company

The Lehigh Crane Iron Company was a major ironmaking firm in the Lehigh Valley from its founding in 1839 until its sale in 1899. It was founded under the patronage of the Lehigh Coal and Navigation Company, which hoped to promote the then-novel technique of smelting iron ore with anthracite coal...

to make use of the process.

For steel the hot blast temperature can be from 900 °C to 1300 °C (1600 °F to 2300 °F) depending on the stove design and condition. The temperatures they deal with may be 2000 °C to 2300 °C (3600 °F to 4200 °F). Oil

Oil

An oil is any substance that is liquid at ambient temperatures and does not mix with water but may mix with other oils and organic solvents. This general definition includes vegetable oils, volatile essential oils, petrochemical oils, and synthetic oils....

, tar

Tar

Tar is modified pitch produced primarily from the wood and roots of pine by destructive distillation under pyrolysis. Production and trade in tar was a major contributor in the economies of Northern Europe and Colonial America. Its main use was in preserving wooden vessels against rot. The largest...

, natural gas

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

, powdered coal

Coal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

and oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

can also be injected into the furnace at tuyere

Tuyere

A tuyere, also can be spelled as tuyère, is a tube, nozzle or pipe through which air is blown into a furnace or hearth.Air or oxygen is injected into a hearth under pressure from bellows or a blast engine or other devices...

level to combine with the coke to release additional energy which is necessary to increase productivity.