Anagama kiln

Encyclopedia

Pottery

Pottery is the material from which the potteryware is made, of which major types include earthenware, stoneware and porcelain. The place where such wares are made is also called a pottery . Pottery also refers to the art or craft of the potter or the manufacture of pottery...

kiln brought to Japan

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

from China

China

Chinese civilization may refer to:* China for more general discussion of the country.* Chinese culture* Greater China, the transnational community of ethnic Chinese.* History of China* Sinosphere, the area historically affected by Chinese culture...

via Korea

Korea

Korea ) is an East Asian geographic region that is currently divided into two separate sovereign states — North Korea and South Korea. Located on the Korean Peninsula, Korea is bordered by the People's Republic of China to the northwest, Russia to the northeast, and is separated from Japan to the...

in the 5th century.

An anagama (a Japanese term meaning "cave kiln

Kiln

A kiln is a thermally insulated chamber, or oven, in which a controlled temperature regime is produced. Uses include the hardening, burning or drying of materials...

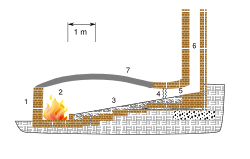

") consists of a firing chamber with a firebox at one end and a flue at the other. Although the term "firebox" is used to describe the space for the fire, there is no physical structure separating the stoking space from the pottery space. The term anagama describes single-chamber kilns built in a sloping tunnel shape. In fact, ancient kilns were sometimes built by digging tunnels into banks of clay.

The anagama is fueled with firewood, in contrast to the electric or gas-fueled kilns commonly used by most contemporary potters

Pottery

Pottery is the material from which the potteryware is made, of which major types include earthenware, stoneware and porcelain. The place where such wares are made is also called a pottery . Pottery also refers to the art or craft of the potter or the manufacture of pottery...

. A continuous supply of fuel is needed for firing, as wood thrown into the hot kiln is consumed very rapidly. Stoking occurs round the clock until a variety of variables are achieved including the way the molten pots look inside the kiln, the temperatures reached and sustained, the amount of ash applied, the wetness of the walls and the pots, etc.

Fly ash

Fly ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal...

and volatile salts. Wood ash settles on the pieces during the firing, and the complex interaction between flame, ash, and the minerals of the clay body forms a natural ash glaze. This glaze may show great variation in color, texture, and thickness, ranging from smooth and glossy to rough and sharp. The placement of pieces within the kiln distinctly affects the pottery's appearance, as pieces closer to the firebox may receive heavy coats of ash, or even be immersed in embers, while others deeper in the kiln may only be softly touched by ash effects. Other factors that depend on the location include temperature and oxidation/reduction

Redox

Redox reactions describe all chemical reactions in which atoms have their oxidation state changed....

. Besides location in the kiln, (as with other fuel-fired updraft kilns) the way pieces are placed near each other affects the flame path, and, thus, the appearance of pieces within localized zones of the kiln can vary as well. It is said that loading an anagama kiln is the most difficult part of the firing. The potter must imagine the flame path as it rushes through the kiln, and use this sense to paint the pieces with fire.

The length of the firing depends on the volume of the kiln and may take anywhere from 48 hours to 12 days or more. The kiln generally takes the same amount of time to cool down. Records of historic firings in large Asian kilns shared by several village potters describe several weeks of steady stoking per firing.

Kiln variants

One variant on the anagama style is the waritake kiln. A waritake kiln is akin to anagama in structure, but it has partition walls built every several meters through the length of the kiln. Each partition can be side stoked.

The Renboshiki noborigama is a multi-chambered climbing kiln. There are many distinguishing characteristics between the noborigama and anagama style. For example, an anagama is somewhat like a half-tube (long vault

Vault (architecture)

A Vault is an architectural term for an arched form used to provide a space with a ceiling or roof. The parts of a vault exert lateral thrust that require a counter resistance. When vaults are built underground, the ground gives all the resistance required...

) with a fire burned at the lower end. A noborigama is like a set of half-tubes (arch

Arch

An arch is a structure that spans a space and supports a load. Arches appeared as early as the 2nd millennium BC in Mesopotamian brick architecture and their systematic use started with the Ancient Romans who were the first to apply the technique to a wide range of structures.-Technical aspects:The...

es or short vaults, buttress

Buttress

A buttress is an architectural structure built against or projecting from a wall which serves to support or reinforce the wall...

ing each other) placed side-by-side with piercings that allow each chamber to feed into the next.

The jagama (snake kiln or dragon kiln) is related to anagama, noborigama, and waritake kilns, and was used extensively in China for thousands of years. Jagama are tube shaped similarly to anagama kilns, but they can be very long—200' (60 m) is not unreasonable. Although partitioned and side stoked, jagama do not have partition walls, rather, improvised walls are created by densely stacking pottery at intervals.

Characteristics of climbing kilns

The main advantage of climbing kilns is that heat from the burning fuel is re-used, the same heat heating more than one part of the kiln. Exhaust heat created during firing of the lower part of the kiln, preheats the chambers above. In addition, the cooling ware and walls below preheat the incoming air. Thus, firing of ware in the upper chambers requires only the additional fuel needed to bring the ware, walls and air to peak temperature. (From a thermodynamicThermodynamics

Thermodynamics is a physical science that studies the effects on material bodies, and on radiation in regions of space, of transfer of heat and of work done on or by the bodies or radiation...

point of view, the higher temperature of combustion and cooler exhaust suggest greater efficiency.) The fuel efficiency of this type of design may have been essential for high temperature ceramics to be economically viable in Asia long (perhaps a thousand years) before the use of coal in Europe. (A modern type, called a tube kiln improves the efficiency and output still further by having the ware move through the kiln in a direction opposite to that of the hot gasses.)

All of these kilns use two counter-flow exchange mechanisms to maintain the air supply and to change the ware being fired, with minimal loss of heat. Each of these exchanges works on the same principle as countercurrent exchange

Countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some component, between two flowing bodies flowing in opposite directions to each other. The flowing bodies can be liquids, gases, or...

, the principal difference being that the ware is not a fluid.

An advantage of the chambered and semi-chambered variants appears to be that they are partly downdraft, which makes the firing results less sensitive to the way the ware is loaded.

A disadvantage of (small) climbing kilns is a tendency to rapid cooling, caused by the incoming air.

External links

- Cofield, Jay. "Montevallo's Anagama." Southern Spaces, 10 June 2008.

- Young International Woodfirer Association, an international association of people building and using Anagama kilns and other woodfired kilns

- The Log Book, the magazine about anagamas and woodfiring in general

- Ken Shenstone and David Smith, participants in the pioneering American woodfiring tradition

- An anagama kiln built according to Furutani Michio's design principles, podcasts with woodfire potters, photogalleries of woodfired work

- Carlson, Scott. Earth, Wind, and Fire: Richard Bresnahan's elemental approach to art — and life Chronicle of Higher Education, 13 February 2009. A story about a potter who built the Johanna Kiln, the largest wood-fired kiln in North America.

- Anagama kilns built by Gas Kanashima, a Japanese potter working in England.