Worst case circuit analysis

Encyclopedia

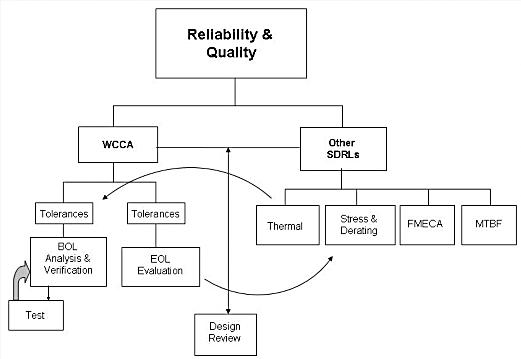

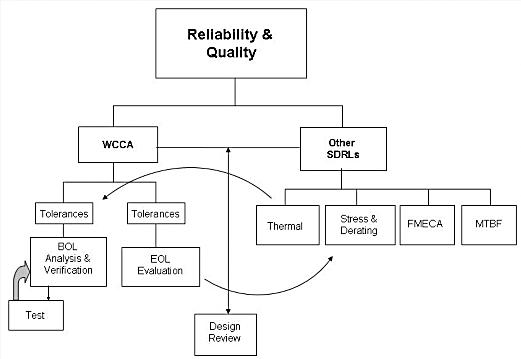

Worst-case circuit analysis (WCCA or WCA) is a cost-effective means of screening a design to ensure with a high degree of confidence that potential defects and deficiencies are identified and eliminated PRIOR TO and DURING test, production, and delivery.

It is a quantitative assessment of the equipment performance, accounting for manufacturing, environmental and aging effects. In addition to a circuit analysis, a WCCA often includes stress and derating

analysis, Failure Modes and Effects Criticality (FMECA

) and Reliability Prediction (MTBF).

The specific objective is to verify that the design is robust enough to provide operation which meets the system performance specification over design life under worst-case conditions and tolerances (initial, aging, radiation, temperature, etc.).

Stress and De rating Analysis is intended to increase reliability by providing sufficient margin compared to the allowable stress limits. This reduces overstress conditions that may induce failure, and reduces the rate of stress-induced parameter change over life. It determines the maximum applied stress to each component in the system.

This analysis is performed using SPICE and mathematical models of individual circuits within the device or system to determine the sensitivities. A spreadsheet program is used to total and summarize the results.

A WCCA follows this general form:

The design is broken down into the appropriate functional sections. A mathematical model of the circuit is developed and the effects of various part/system tolerances are applied. The circuit's EVA and RSS results are determined for Beginning-of-Life and End-of-Life states.

Two methods of analysis and/or hardware correlation are always used to confirm results.

These results are used to calculate part stresses and are applied to other analysis. In order for the WCCA to be useful throughout the product’s life cycle, it is extremely important that the analysis be documented in a clear and concise format. This will allow for future updates and review by other than the original designer. A compliance matrix is generated that clearly identifies the results and all issues.

It is a quantitative assessment of the equipment performance, accounting for manufacturing, environmental and aging effects. In addition to a circuit analysis, a WCCA often includes stress and derating

Derating

Derating is the operation of a machine at less than its rated maximum power in order to prolong its life. The term is commonly applied to electrical and electronic devices and to internal combustion engines.-In electronics:...

analysis, Failure Modes and Effects Criticality (FMECA

FMECA

Failure mode, effects and criticality analysis is an extension of failure mode and effects analysis . FMEA is a bottom-up, inductiveanalytical method which may be performed at either the functional or piece-part level...

) and Reliability Prediction (MTBF).

The specific objective is to verify that the design is robust enough to provide operation which meets the system performance specification over design life under worst-case conditions and tolerances (initial, aging, radiation, temperature, etc.).

Stress and De rating Analysis is intended to increase reliability by providing sufficient margin compared to the allowable stress limits. This reduces overstress conditions that may induce failure, and reduces the rate of stress-induced parameter change over life. It determines the maximum applied stress to each component in the system.

General Information

A worst case circuit analysis should be performed on all circuitry that is safety and financially critical. Worst case circuit analysis is an analysis technique which, by accounting for component variability, determines the circuit performance under a worst case scenario(Under extreme environmental or operating conditions). Environmental conditions are defined as external stresses applied to each circuit component. It includes temperature,humidity or radiation. Operating conditions include external electrical inputs. Component quality level, interaction between parts, and drift due to component aging.Methodology

Worst-case analysis is the analysis of a device or system that assures that the device meets its performance specifications. These are typically accounting for tolerances that are due to initial component tolerance, temperature tolerance, age tolerance and environmental exposures (such as radiation for a space device). The beginning of life analysis comprises the initial tolerance and provides the data sheet limits for the manufacturing test cycle. The end of life analysis provides the additional degradation resulting from the aging and temperature effects on the elements within the device or system.

This analysis is performed using SPICE and mathematical models of individual circuits within the device or system to determine the sensitivities. A spreadsheet program is used to total and summarize the results.

A WCCA follows this general form:

- Generate/Obtain circuit model

- Obtain Correlation to validate model

- Determine sensitivity to each component parameter

- Determine component tolerances

- Calculate the variance of each component parameter as sensitivity times absolute tolerance

- Use at least two methods of analysis (eg. hand analysis and SPICE or Saber, SPICE and measured data) to assure the result

- Generate a formal report to convey the information produced

The design is broken down into the appropriate functional sections. A mathematical model of the circuit is developed and the effects of various part/system tolerances are applied. The circuit's EVA and RSS results are determined for Beginning-of-Life and End-of-Life states.

Two methods of analysis and/or hardware correlation are always used to confirm results.

These results are used to calculate part stresses and are applied to other analysis. In order for the WCCA to be useful throughout the product’s life cycle, it is extremely important that the analysis be documented in a clear and concise format. This will allow for future updates and review by other than the original designer. A compliance matrix is generated that clearly identifies the results and all issues.