Rotating biological contactor

Encyclopedia

Wastewater

Wastewater is any water that has been adversely affected in quality by anthropogenic influence. It comprises liquid waste discharged by domestic residences, commercial properties, industry, and/or agriculture and can encompass a wide range of potential contaminants and concentrations...

following primary treatment. The primary treatment process removes the grit

Grit

Grit may refer to:* GRIT , also known as Arhgap32 or PX-RICS* Grit , a U.S. periodical founded as a newspaper in 1882* Grit , by Celtic fusion musician Martyn Bennett* Grit , by Norwegian rock band Madrugada...

and other solids through a screening process followed by a period of settlement. The RBC process involves allowing the wastewater to come in contact with a biological medium in order to remove pollutant

Pollutant

A pollutant is a waste material that pollutes air, water or soil, and is the cause of pollution.Three factors determine the severity of a pollutant: its chemical nature, its concentration and its persistence. Some pollutants are biodegradable and therefore will not persist in the environment in the...

s in the wastewater before discharge of the treated wastewater to the environment

Natural environment

The natural environment encompasses all living and non-living things occurring naturally on Earth or some region thereof. It is an environment that encompasses the interaction of all living species....

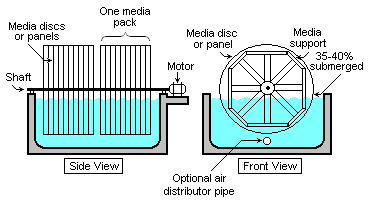

, usually a body of water (river, lake or ocean). A rotating biological contactor is a type of secondary treatment process. It consists of a series of closely spaced, parallel discs mounted on a rotating shaft which is supported just above the surface of the waste water. Microorganisms grow on the surface of the discs where biological degradation of the wastewater pollutants takes place.

Biotechnology for wastewater

Environmental consciousness and concern sustainable society have driven the society to the direction of re-organization of the infrastructures and the urban systems. To build an environmental management system that satisfies various social needs simultaneously in the water environment, it is essential to optimize environmental control technologies by comprehensive and systematic approaches. In this course, we critically discuss several key issues that are important in achieving desirable environmental technology systems.Biochemistry to understand the technology of wastewater treatment technologies using microorganisms is the main topic.

The characteristics of complex microbial community and mathematical design modeling for Rotating Biological Contactors are discussed in this project.

Biotechnology for wastewater treatment is needed so that we can use our rivers and stream for fishing, swimming and drinking water. For the first half of the 20th century, population in the Nation’s urban waterways resulted in frequent occurrences of low dissolved oxygen, fish kills, algal blooms and bacterial contamination. Early efforts in water pollution control prevented human waste from reaching water supplies or reduced floating debris that obstructed shipping. Pollution problems and their control were primarily local, not national, concerns. Since then, population and industrial growth have increased demand on our natural resources, altering the situation dramatically. Progress in abating pollution has barely kept ahead of population growth, changes in industrial processes, technological developments, and changes in land use, business innovations, and many other factors. Increases in both the quantity and variety of goods produced can greatly alter the amount and complexity of industrial wastes and challenge traditional treatment technology. The application of commercial fertilizers and pesticides, combined with sediment from growing development activities, continue to be source of significant pollution as runoff washes off the land.

Water pollution issues now dominate public concerns about national water quality and maintaining healthy ecosystems. Although a large investment in water pollution control has helped to reduce the problems, many miles of streams are still impacted by variety of different pollutants. This, in turn, affects the ability of people to use the water for beneficial purpose. Past approaches used to control must be modified to accommodate current and emerging issues. Hence the appropriate biotechnology should be used for wastewater treatment plant.

Operation

The rotating packs of disks (known as the media) are contained in a tank or trough and rotate at between 2 and 5 revolutions per minute. Commonly used plastics for the media are polythene, PVCPVC

Polyvinyl chloride is a plastic.PVC may also refer to:*Param Vir Chakra, India's highest military honor*Peripheral venous catheter, a small, flexible tube placed into a peripheral vein in order to administer medication or fluids...

and expanded polystyrene

Polystyrene

Polystyrene ) also known as Thermocole, abbreviated following ISO Standard PS, is an aromatic polymer made from the monomer styrene, a liquid hydrocarbon that is manufactured from petroleum by the chemical industry...

. The shaft is aligned with the flow of wastewater so that the discs rotate at right angles to the flow with several packs usually combined to make up a treatment train. About 40% of the disc area is immersed in the wastewater.

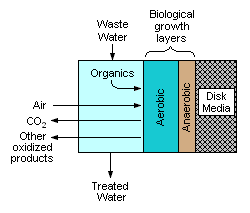

Biological growth is attached to the surface of the disc and forms a slime layer. The disc contact wastewater and air for oxidation as it rotates. Helps to slough off excess solids. About one third of the disc is submerged. The disc system can be staged in series to obtain nearly any detention time or degree of removal required. Since the systems are staged, the culture of the later stages can be acclimated to the slowly degraded materials.

RBC media in the form of large, flat disc mounted on common shaft are rotated through specially contoured tanks in which waste water flow on a continuous basis. The medium consists of plastic sheets ranging from 2 to 4 m in dia and up to 10 mm thick. Several modules may be arranged in parallel and / or in series to meet the flow and treatment requirements. The discs are submerged in waste water to about 40% of there diameter and are rotated by power supplied to the shaft.

Approximately 95% of the surface area is thus alternately immerged in waste water in then exposed to the atmosphere above the liquid under normal operating conditions; carbonaceous substrate is removed in the initial stage of RBC. Carbon conversion may be completed in the first stage of a series of modules, with nitrification being completed after the 5th stage. Most design of RBC systems will include a minimum of 4 or 5 modules in series to obtain nitrification of waste water.

Aeration

Aeration is the process by which air is circulated through, mixed with or dissolved in a liquid or substance.-Aeration of liquids:-Methods:Aeration of liquids is achieved by:...

is provided by the rotating action, which exposes the media to the air after contacting them with the wastewater, facilitating the degradation of the pollutants being removed. The degree of wastewater treatment is related to the amount of media surface area and the quality and volume of the inflowing wastewater.

RBC’s were first installed in West Germany in 1960 and were later introduce in U.S and Canada, 70% of the RBC systems installed are used for carbonaceous. BOD removal only,25 % for combine carbonaceous BOD removal and nitrification, and 5% for the nitrification of secondary effluent.

Construction

Rotating Biological contactor is the attached growth process.Rotating biological consist of 3-4m diameter plastic sheet of thickness 10mm attached to a shaft which is connected to a motor power 40kW, rotate at 1-2 rpm.

1 module contains 4-6 discs. And 5-6 module in series to assure complete nitrification

Process-in this process the disc rotate in the tank at 1-2 rpm to assure proper growth of bio logical film on the disc. The disc is submerged in the waste water about 45% to 90% of it dia according to the characteristic of waste water.

When the disc rotates outside the tank the air enters the voids of the disc and water inside the disc trickles out the surface of the disc on the biological growth. During the submergence period the microbes present in the waste water get attached to the disc and from a bio-logical film. The film is around 3-4mm thick. This film when enter in to the waste water it consumes the organic waste by breaking the complex organic matter into the compound organic matter. Again when the disc surface faces the open atmosphere to receive enough oxygen to sustain and carry out their metabolic activities. Since the bio film is oxygenated externally from the wastewater, aerobic condition may develop in the liquid.

Under normal operating condition the carbonaceous sustain in the initial stage of RBC. The carbon conversion may be completed in the first stage of a series of modules with nitrification being completed after the fifth stage. Nitrification proceeds only after carbon concentration is substantially reduced. Most design of RBC system will include minimum of four to five module in series to obtain nitrification of wastewater. The sloughed bio mass is relatively dense and settles well in secondary clarifier. Since it is continuous process it has no detention time.

History

The first RBC was installed in Germany in 1960, later it was introduced in U.S.A. In U.S.A Rotating biological contactors are used for industries producing high B.O.D. i.e. for petroleum industry, dairy industries etc.

Detail:- size of disc- <1m up to 5m

Length of shaft- up to 8m

Disc material: PVC is commonly used.

Plastic media is typically 1-2mm thick and corrugated for strength.

Submergence of disc in wastewater: 40 - 100%.

Speed of disc -: 1-2 rpm (revolutions per minute)

Hydraulic loading -: 30 – 160 lit/day/m²

Organic loading -: 5 to 20 gBOD/day/m²

Film of micro organism on disc -: 1-2mm as per characteristics of wastewater.

Detention time -: 40 mins - 4 hours.

The rotating biological contactor reactor is a unique adaptation of the attached-growth process. Media in the form of large, flat disks mounted on a common shaft are rotated through specially contoured tanks in which wastewater flows on a continuous basis.

The medium consist of many plastic sheets of up to 4 m in diameter, arranged on a central horizontal shaft. Spacing between flat disks is approximately 15 to 40 mm.

The discs are submerged in wastewater to about 40 percent of their diameter and are rotated by electric motor via a gearbox, or by air or water drive. The discs are alternately immersed in the waste water and then exposed to the atmosphere above the liquid. Rotational speed of the unit ranges from 1 to 2 r/min. Micro-organisms growing on the medium surface remove nutrients from the wastewater and consume oxygen from the air to sustain their metabolic processes. As the biofilm grows and thickens, anaerobic conditions may develop in the lower layers and parts of the biofilm will slough from the media, to be replaced by new growth.

Under normal operating conditions, carbonaceous substrate (BOD) is removed in the initial stages of the R.B.C. and nitrification occurs in later stages. The stages may be configured as multiple RBCs in series, or by modules of media plates within a single R.B.C..

Most designs of R.B.C include minimum of 4 to 5 module in series to obtain nitrification of the wastewater. One module of 3.7 m in diameter by 7.6 m long contains approximately 10,000 m² of surface area for bio-film growth. A 40-kw motor is sufficient to turn the 3.7 by 7.6 m unit.

Secondary clarification

Secondary clarifiers following R.B.C.s are identical in design to conventional humus tanks, as used downstream of trickling filters. Sludge is generally removed daily, or pumped automatically to the primary settlement tank for co-settlement. Regular sludge removal reduces the risk of anaerobic conditions from developing within the sludge, with subsequent sludge flotation due to the release of gases.See also

- Activated sludgeActivated sludgeActivated sludge is a process for treating sewage and industrial wastewaters using air and a biological floc composed of bacteria and protozoans.-Purpose:...

- Aerated lagoonAerated lagoonAn aerated lagoon or aerated basin is a holding and/or treatment pond provided with artificial aeration to promote the biological oxidation of wastewaters. There are many other biological processes for treatment of wastewaters, for example activated sludge, trickling filters, rotating biological...

- Trickling filterTrickling filterA trickling filter consists of a fixed bed of rocks, lava, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime to grow, covering the bed of media...

- Industrial wastewater treatmentIndustrial wastewater treatmentIndustrial wastewater treatment covers the mechanisms and processes used to treat waters that have been contaminated in some way by anthropogenic industrial or commercial activities prior to its release into the environment or its re-use....

- List of waste water treatment technologies

- Sewage treatmentSewage treatmentSewage treatment, or domestic wastewater treatment, is the process of removing contaminants from wastewater and household sewage, both runoff and domestic. It includes physical, chemical, and biological processes to remove physical, chemical and biological contaminants...