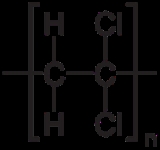

Polyvinylidene chloride

Encyclopedia

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

derived from vinylidene chloride.

History

Ralph Wiley, a Dow Chemical lab worker, accidentally discovered polyvinylidene chloride in 1933. While cleaning laboratory glassware, he came across a vial he could not scrub clean. Dow researchers made this material into a greasy, dark green film, first called "Eonite" and then "SaranSaran (plastic)

Saran is the trade name for a number of polymers made from vinylidene chloride , along with other monomers. The main advantage of Saran film is its very low permeability to water vapor, flavor and aroma molecules, and oxygen compared with other plastics...

".

Ralph Wiley went on to become one of Dow Chemical's Research Scientists and invent and develop many plastics, chemicals and production machines.

The military sprayed Saran on fighter planes to guard against salty sea spray and carmakers used it for upholstery. Dow later devised a formulation of polyvinylidene chloride free of unpleasant odour and green colour.

The most well known use of polyvinylidene chloride came in 1953, when Saran Wrap, a plastic food wrap was introduced. In 2004, however, the formula was changed to low density polyethylene

Low density polyethylene

Low-density polyethylene is a thermoplastic made from petroleum. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries using a high pressure process via free radical polymerization. Its manufacture employs the same method today. LDPE is commonly recycled and has...

due to environmental concerns about its chlorine content.

Production methods

Saran fiber is manufactured by melt spinning vinylidene chloride copolymer. Saran is pigment dyed before fiberspinning if color is desired.Fiber properties

Saran fiber is a heavy fiber. It is a remarkable barrier against water, oxygen and aromas, has superior chemical resistance to alkalis and acids, is insoluble in oil and organic solvents, has very low moisture regain and is impervious to mold, bacteria, and insects. Saran fiber has a high elastic recovery and resists wrinkling and creasing. Because it is pigment dyed before fiberspinning, it has excellent colorfastness and high light permeability. Saran is also flame-retardant and self extinguishing, it may soften or char in flame, and decomposes in moderate heat.Fiber types

Saran fiber comes in monofilament, multifilament-twist, and as a staple fiber. It is also available in thermochromic (color changing) and luminescent (glow in the dark) fibers.Packaging

Polyvinylidene chloride is applied as a water-based coating to other plastic films such as biaxially-oriented polypropylenePolypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

(BOPP) and polyester

Polyester

Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term "polyester" as a specific material most commonly refers to polyethylene terephthalate...

(PET). This coating increases the barrier properties of the film, reducing the permeability of the film to oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

and flavours and thus extending the shelf life

Shelf life

Shelf life is the length of time that food, drink, medicine, chemicals, and many other perishable items are given before they are considered unsuitable for sale, use, or consumption...

of the food inside the package.

Disadvantages

While extremely useful as a food packaging agent, the major disadvantage of Saran is that it will undergo thermally induced dehydrochlorination at temperatures very near to processing temperatures. This degradation easily propagates, leaving polyene sequences long enough to absorb visible light, and change the color of the material from colorless to an undesirable transparent brown (unacceptable for one of Saran's chief applications: food packaging). Therefore, there is a significant amount of product loss in the manufacturing process, which increases production and consumer costs.Trademarks (producers)

Saran TC and Saran LS (Asahi-Kasei), Saran Wrap and Saranex (Dow Chemical), Ixan and Diofan (SolVin)See also

- Wiley mini-bio

- Textile Fibre Database

- Olympus Micro

- Dow Chemical