Hard disk platter

Encyclopedia

Floppy disk

A floppy disk is a disk storage medium composed of a disk of thin and flexible magnetic storage medium, sealed in a rectangular plastic carrier lined with fabric that removes dust particles...

). Hard drives typically have several platters which are mounted on the same spindle. A platter can store information on both sides, requiring two heads per platter.

Description

The magnetic surface of each platter is divided into small sub-micrometer-sized magnetic regions, each of which is used to represent a single binary unit of information. A typical magnetic region on a hard-disk platter (as of 2006) is about 200–250 nanometers wide (in the radial direction of the platter) and extends about 25–30 nanometers in the down-track direction (the circumferential direction on the platter), corresponding to about 100 billion bits (100 gigabitGigabit

The gigabit is a multiple of the unit bit for digital information or computer storage. The prefix giga is defined in the International System of Units as a multiplier of 109 , and therefore...

s) per square inch of disk area. The material of the main magnetic medium layer is usually a cobalt-based alloy. In today's hard drives each of these magnetic regions is composed of a few hundred magnetic grains, which are the base material that gets magnetized. As a whole, each magnetic region will have a magnetization.

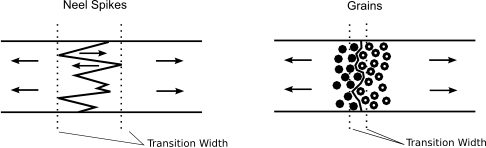

One reason magnetic grains are used as opposed to a continuous magnetic medium is that they reduce the space needed for a magnetic region. In continuous magnetic materials, formations called Neel spikes tend to appear. These are spikes of opposite magnetization, and form for the same reason that bar magnets will tend to align themselves in opposite directions. These cause problems because the spikes cancel each other's magnetic field

Magnetic field

A magnetic field is a mathematical description of the magnetic influence of electric currents and magnetic materials. The magnetic field at any given point is specified by both a direction and a magnitude ; as such it is a vector field.Technically, a magnetic field is a pseudo vector;...

out, so that at region boundaries, the transition from one magnetization to the other will happen over the length of the Neel spikes. This is called the transition width.

Weiss domains

Weiss domains are small areas in a crystal structure of a ferromagnetic material with uniformly oriented magnetic momenta. They were named after the French physicist Pierre-Ernest Weiss ....

(though not always in practice). This means that the magnetic domains cannot grow or shrink to form spikes, and therefore the transition width will be on the order of the diameter of the grains. Thus, much of the development in hard drives has been in reduction of grain size.

Manufacture

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

or glass

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

and ceramic

Ceramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

substrate. In disk manufacturing, a thin coating is deposited on both sides of the substrate, mostly by a vacuum deposition

Vacuum deposition

Vacuum deposition is a family of processes used to deposit layers atom-by-atom or molecule-by-molecule at sub-atmospheric pressure on a solid surface. The layers may be as thin as one atom to millimeters thick . There may be multiple layers of different materials...

process called magnetron sputtering

Sputter deposition

Sputter deposition is a physical vapor deposition method of depositing thin films by sputtering, that is ejecting, material from a "target," that is source, which then deposits onto a "substrate," such as a silicon wafer...

. The coating has a complex layered structure consisting of various metallic (mostly non-magnetic) alloys as underlayers, optimized for the control of the crystallographic orientation and the grain size of the actual magnetic media layer on top of them, i.e. the film storing the bits of information. On top of it a protective carbon-based overcoat is deposited in the same sputtering process. In post-processing a nanometer thin polymeric lubricant layer gets deposited on top of the sputtered structure by dipping the disk into a solvent solution, after which the disk is buffed by various processes to eliminate small defects and verified by a special sensor on a flying head for absence of any remaining impurities or other defects (where the size of the bit given above roughly sets the scale for what constitutes a significant defect size). In the hard-disk drive the hard-drive heads

Disk read-and-write head

Disk read/write heads are the small parts of a disk drive, that move above the disk platter and transform platter's magnetic field into electrical current or vice versa – transform electrical current into magnetic field...

fly and move radially over the surface of the spinning platters to read or write the data. Extreme smoothness, durability, and perfection of finish are required properties of a hard-disk platter.

In 2005–06, a major shift in technology of hard-disk drives and of magnetic disks/media began. Originally, in-plane magnetized materials were used to store the bits but perpendicular magnetization is now taking over. (see perpendicular recording

Perpendicular recording

Perpendicular recording is a technology for data recording on hard disks. It was first proven advantageous in 1976 by Shun-ichi Iwasaki, then professor of the Tohoku University in Japan, and first commercially implemented in 2005.-Advantages:Perpendicular recording can deliver more than three...

).

The reason for this transition is the need to continue the trend of increasing storage densities, with perpendicularly oriented media offering a more stable solution for a decreasing bit size. Orienting the magnetization perpendicular to the disk surface has major implications for the disk's deposited structure and the choice of magnetic materials, as well as for some of the other components of the hard-disk drive (such as the head and the electronic channel).