Co-axial escapement

Encyclopedia

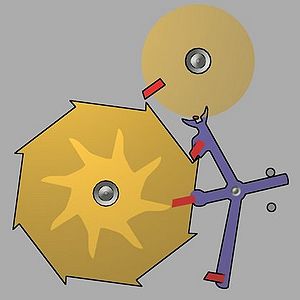

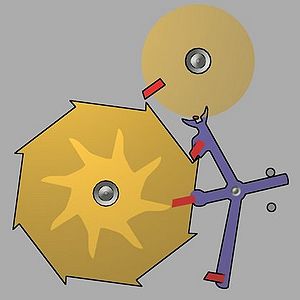

Co-axial escapement is a type of modern watch escapement

mechanism invented by English watchmaker George Daniels.

with some features of the detent escapement. Considered by many to be one of the most significant horological

advancements since the invention of the lever escapement, the co-axial escapement functions with a system of 3 pallets that separates the locking function from the impulse, avoiding the sliding friction of the lever escapement. This makes lubrication of the pallets unnecessary and thereby eliminating one of the shortcomings of the traditional lever escapement.

Escapement

In mechanical watches and clocks, an escapement is a device that transfers energy to the timekeeping element and enables counting the number of oscillations of the timekeeping element...

mechanism invented by English watchmaker George Daniels.

Overview

Invented around 1974 and patented 1980 by English watchmaker George Daniels, the Co-axial escapement is a modification of the lever escapementLever escapement

The lever escapement is a key component of the typical movement found in most mechanical wristwatches, pocket watches and many small mechanical non-pendulum clocks....

with some features of the detent escapement. Considered by many to be one of the most significant horological

Horology

Horology is the art or science of measuring time. Clocks, watches, clockwork, sundials, clepsydras, timers, time recorders and marine chronometers are all examples of instruments used to measure time.People interested in horology are called horologists...

advancements since the invention of the lever escapement, the co-axial escapement functions with a system of 3 pallets that separates the locking function from the impulse, avoiding the sliding friction of the lever escapement. This makes lubrication of the pallets unnecessary and thereby eliminating one of the shortcomings of the traditional lever escapement.

Critical virtue

The critical virtue of the Daniels Escapement is the virtual elimination of the sliding friction component, i.e. the sliding of the pallet stones over the teeth of the escape wheel. What little sliding friction remains is due to the impossibility of maintaining an exact tangential geometry throughout the duration of an impulse.Radial friction vs. sliding friction

By utilizing radial friction instead of sliding friction at the impulse surfaces the co-axial escapement significantly reduces friction, theoretically resulting in longer service intervals and greater accuracy over time.Commercialization

The escapement was commercialized in 1999 by Omega SA when it introduced the first mass-produced watch incorporating the technology. When it first came to the market as the Caliber 2500, it had an oscillation rate of 28,800 bph, considered a "hi-beat" movement. But the rate was reduced to 25,200 bph in the Caliber 2500C. "While Daniels has recognized the advantages of higher beat movements, he has also noted that they aggravate the problem of sliding friction in the escapement (at the escape teeth and pallets). Higher beat movements produce increased speed and pressure at these critical surfaces."External links

- Description and animation of Omega's co-axial escapement

- The Omega Co-axial:An Impressive Achievement by Walt Odets

- Performance of the Daniels Coaxial Escapement by Phillip Woodward

- Questions in Time column about the history leading to the co-axial escapement by Professor J.C. Nicolet

- Clear images, and an animation, of the co-axial escapement by Siméon Lapinbleu

- line drawing animation of the daniels co-axial escapement Mark Headrick's Horology Page