Chevron CRUSH

Encyclopedia

Chevron CRUSH is an in situ

shale oil extraction technology to convert kerogen

in oil shale

to shale oil

. The name stands for Chevron's Technology for the Recovery and Upgrading of Oil from Shale. It is developed jointly by Chevron Corporation

and the Los Alamos National Laboratory

.

, the Sandia National Laboratories

, and the Laramie Energy Technology Center of the U.S. Department of Energy emploed explosive and hydraulic fracturing technologies. Equity Oil Company, Continental Oil Company and the University of Akron

studied the benefit of carbon dioxide as a carrier gas to facilitate a higher yield of shale oil. Based on these works, Chevron Corporation and the Los Alamos National Laboratory started a cooperation in 2006 to improve the recovery of hydrocarbons from oil shale. IN 2006, the United States Department of the Interior issued a research, development and demonstration lease for Chevron's demonstration project on public lands in Colorado’s Piceance Basin

.

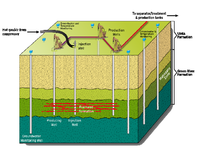

For decomposition kerogen in oil shale, the Chevron CRUSH process uses heated carbon dioxide

For decomposition kerogen in oil shale, the Chevron CRUSH process uses heated carbon dioxide

. The process involves drilling vertical wells into the oil shale formation and applying horizontal fractures induced by injecting carbon dioxide through drilled wells and then pressured through the formation for circulation through the fractured intervals to rubblize the production zone. For further rubblization propellants and explosives may be used. The used carbon dioxide then be routed to the gas generator to be reheated and recycled. The remaining organic matter in previously heated and depleted zones is combusted in-situ to generate the heated gases required to process successive intervals. These gases would then be pressured from the depleted zone into the newly fractured portion of the formation and the process would be repeated. The hydrocarbon fluids are brought up in conventional vertical oil wells.

In situ

In situ is a Latin phrase which translated literally as 'In position'. It is used in many different contexts.-Aerospace:In the aerospace industry, equipment on board aircraft must be tested in situ, or in place, to confirm everything functions properly as a system. Individually, each piece may...

shale oil extraction technology to convert kerogen

Kerogen

Kerogen is a mixture of organic chemical compounds that make up a portion of the organic matter in sedimentary rocks. It is insoluble in normal organic solvents because of the huge molecular weight of its component compounds. The soluble portion is known as bitumen. When heated to the right...

in oil shale

Oil shale

Oil shale, an organic-rich fine-grained sedimentary rock, contains significant amounts of kerogen from which liquid hydrocarbons called shale oil can be produced...

to shale oil

Shale oil

Shale oil, known also as kerogen oil or oil-shale oil, is an unconventional oil produced from oil shale by pyrolysis, hydrogenation, or thermal dissolution. These processes convert the organic matter within the rock into synthetic oil and gas...

. The name stands for Chevron's Technology for the Recovery and Upgrading of Oil from Shale. It is developed jointly by Chevron Corporation

Chevron Corporation

Chevron Corporation is an American multinational energy corporation headquartered in San Ramon, California, United States and active in more than 180 countries. It is engaged in every aspect of the oil, gas, and geothermal energy industries, including exploration and production; refining,...

and the Los Alamos National Laboratory

Los Alamos National Laboratory

Los Alamos National Laboratory is a United States Department of Energy national laboratory, managed and operated by Los Alamos National Security , located in Los Alamos, New Mexico...

.

History

The Chevron CRUSH technology bases on the earlier in situ efforts. Sinclair Oil Corporation conducted an experiment using both natural and induced fractures to establish communication between wells and developing an in situ combustion process. GeokineticsGeokinetics

Geokinetics, Inc. provides seismic data services to the oil and gas industry. It has its headquarters in Westchase, Houston, Texas.Geokinetics is a leading service company offering a broad range of specialized geophysical services to the petroleum and mining industries, worldwide...

, the Sandia National Laboratories

Sandia National Laboratories

The Sandia National Laboratories, managed and operated by the Sandia Corporation , are two major United States Department of Energy research and development national laboratories....

, and the Laramie Energy Technology Center of the U.S. Department of Energy emploed explosive and hydraulic fracturing technologies. Equity Oil Company, Continental Oil Company and the University of Akron

University of Akron

The University of Akron is a coeducational public research university located in Akron, Ohio, United States. The university is part of the University System of Ohio. It was founded in 1870 as a small college affiliated with the Universalist Church. In 1913 ownership was transferred to the City of...

studied the benefit of carbon dioxide as a carrier gas to facilitate a higher yield of shale oil. Based on these works, Chevron Corporation and the Los Alamos National Laboratory started a cooperation in 2006 to improve the recovery of hydrocarbons from oil shale. IN 2006, the United States Department of the Interior issued a research, development and demonstration lease for Chevron's demonstration project on public lands in Colorado’s Piceance Basin

Piceance Basin

The Piceance Basin is a geologic structural basin in northwestern Colorado, in the United States. It includes geologic formations from Cambrian to Holocene in age, but the thickest section is made up of rocks from the Cretaceous Period...

.

Process

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

. The process involves drilling vertical wells into the oil shale formation and applying horizontal fractures induced by injecting carbon dioxide through drilled wells and then pressured through the formation for circulation through the fractured intervals to rubblize the production zone. For further rubblization propellants and explosives may be used. The used carbon dioxide then be routed to the gas generator to be reheated and recycled. The remaining organic matter in previously heated and depleted zones is combusted in-situ to generate the heated gases required to process successive intervals. These gases would then be pressured from the depleted zone into the newly fractured portion of the formation and the process would be repeated. The hydrocarbon fluids are brought up in conventional vertical oil wells.