Barring engine

Encyclopedia

Stationary steam engine

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars , agricultural engines used for ploughing or...

. It is used to avoid the problem of the main engine stopping on its dead centre

Dead centre

In a reciprocating engine, the dead centre is the position of a piston in which it is farthest from, or nearest to, the crankshaft. The former is known as top dead centre while the latter is known as bottom dead centre ....

and so being unable to re-start.

When the main engine is stopped on a dead centre, the barring engine is used to turn it over a fraction of a turn first, leaving it in a more favourable position from which to start.

Barring may also be done to turn the engine over slowly (unloaded) for maintenance, or to prevent belt drives being left too long in one position and taking a "set".

Development

The first barring engines or barring gear were manual. At their simplest, they were a hefty engineer with a crowbar (hence the term 'barring'). The engine's flywheel could be provided with a series of holes or teeth and a roller fulcrumLever

In physics, a lever is a rigid object that is used with an appropriate fulcrum or pivot point to either multiply the mechanical force that can be applied to another object or resistance force , or multiply the distance and speed at which the opposite end of the rigid object travels.This leverage...

set into the frame at a convenient place. Later manual barring engines had geared drives and a crank handle. With suitable reduction gears, even very large engines could be barred by hand. This only needed to be done once a day and was not a hurried operation, so speed was not crucial.

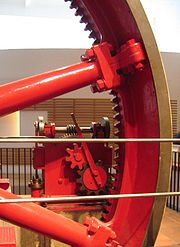

Where a steam barring engine was used this was a small twin-cylinder engine (to avoid its own dead centre problems) with a reduction gear of high ratio, usually involving a worm gear. Final drive was by a pinion gear engaging temporarily with the teeth or barring holes cut into the rim of the main flywheel. The drive pinion was arranged on a swinging link so that it was thrown out-of-mesh automatically, once the main engine started to rotate at full speed. As the ratio was perhaps 1000:1 and the main engine ran at 60 rpm, this would otherwise have been a disastrous overspeed.

As mill engines became more powerful, from around 1870 there was a shift from single belt drives to multiple rope drives. The barring engine needed to turn these rope drives over as well (although they were disconnected from the machinery at the remote end) and a simple manual gear was no longer sufficient. Around 1881–1883 there was a shift to the use of steam-powered barring engines.

Each mill engine manufacturer had their own style of barring engine. Unlike other smaller components, such as feed water pumps, they were rarely bought-in from other makers. Usually though a standard design was used for all sizes of engine, with additional gearing if it was required to bar a particularly large engine.

Preservation today

As barring engines are small, numerous examples have survived into preservation. The Bolton Steam MuseumBolton Steam Museum

Bolton Steam Museum is a museum in Bolton, Greater Manchester, England, which houses a variety of preserved steam engines. It is owned and run by the Northern Mill Engine Society .-Overview:...

has a collection of several.

External links

- Video of barring engine at work – starting a large rotative beam engine at Crossness Pumping StationCrossness Pumping StationCrossness Pumping Station was a sewage pumping station designed by engineer Sir Joseph Bazalgette and architect Charles Henry Driver. It was constructed between 1859 and 1865 as part of his redevelopment of the London sewerage system...

, London