Automatic center punch

Encyclopedia

Hand tool

A hand tool is a device for performing work on a material or a physical system using only hands. The hand tools can be manually used employing force, or electrically powered, using electrical current...

used to produce a dimple in a workpiece (for example, a piece of metal). It performs the same function as an ordinary center punch but without the need for a hammer

Hammer

A hammer is a tool meant to deliver an impact to an object. The most common uses are for driving nails, fitting parts, forging metal and breaking up objects. Hammers are often designed for a specific purpose, and vary widely in their shape and structure. The usual features are a handle and a head,...

. When pressed against the workpiece, it stores energy

Potential energy

In physics, potential energy is the energy stored in a body or in a system due to its position in a force field or due to its configuration. The SI unit of measure for energy and work is the Joule...

in a spring, eventually releasing it as an impulse that drives the punch, producing the dimple.

Operation

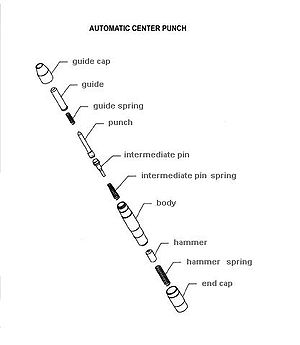

Within the body of the punch, there are three principal moving parts arranged in line:- The punch

- The intermediate rod or pin

- The hammer (hammer mass)

The hammer mass is spring-loaded from the back of the punch by a large spring

Spring (device)

A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after fabrication...

. (The spring's preload compression can be adjusted by loosening or tightening the end cap at the back-most portion of the punch, to decrease or increase the force of the punch.) A stepped hole drilled in the front center portion of the hammer mass facing the intermediate rod acts as a receiver for the rod, and as an anvil for the punch action.

The intermediate rod provides the automation. It's designed with the rod axis off center, so that its resting position is skewed and the tip contacts the hammer mass on that part of the front of the hammer mass where the hole isn't. It bears on the hammer mass and pushes it back against its spring as the punch is pressed, storing up energy in the hammer spring.

As the punch is further pressed against the workpiece, the intermediate rod travels back until a certain point where its midsection begins contacting a cone shaped receiver in the body of the punch. The intermediate rod has a corresponding cone shaped contacting surface, and as it continues back, becomes aligned toward the center axis. When the tip of the intermediate rod is fully aligned and centered, it slips into the receiving hole in the hammer mass, and releases the hammer. The hammer mass is then allowed to move forward, propelled by the rear spring.

Because the stepped hole in the hammer mass is only so deep, the tip of the intermediate rod eventually bottoms out in the hole in the hammer, and the impulse of the hammer mass is transmitted through the intermediate rod, through the punch rod, and into the workpiece.