Automatic Performance Control

Encyclopedia

Automatic Performance Control (APC) was the first engine knock and boost control system that was introduced on turbo charged Saab H engine

s in 1982 and was fitted to all subsequent 900 Turbos through 1993 (and 1994 convertibles), as well as 9000 Turbos through 1989.

The APC allowed a higher compression ratio

The APC allowed a higher compression ratio

(initially, 8.5:1 as opposed to 7.2:1, and, on 16-valve variants introduced in 1985, 9.0:1). This improved fuel economy

and allowed the use of low-octane petrol without causing engine damage caused by knock

.

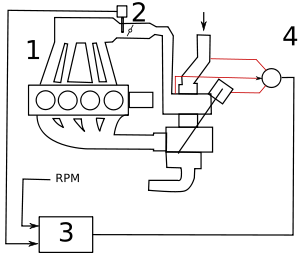

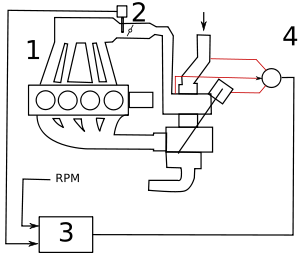

The APC serves two purposes: it controls boost pressure - specifically, the rate of rise and maximum boost level - and it detects and manages harmful knock events.

To control the turbocharger, the APC monitors the engine's RPM

and inlet manifold

pressure

via a pressure transducer

, and uses these inputs to control a solenoid valve that trims the rate of rise of pressure as well as the maximum pressure by directing boost pressure to the turbocharger's pneumatic wastegate actuator.

To detect knock, a piezoelectric knock sensor

(basically a microphone

) bolted to the engine block responds to unique frequencies caused by engine knock. The sensor generates a small voltage that is sent to the electronic control unit

, which processes the signal to determine if, in fact, knock is occurring. If it is, then the control unit activates a solenoid valve that directs boost pressure to the turbocharger's pneumatically controlled wastegate

actuator, which opens the wastegate to bypass exhaust gases from the turbocharger directly to the exhaust pipe, lowering turbo boost pressure until the knock subsides. Knock events that are managed by the APC can be "seen" when the in-dash boost needle "twitches" slightly. The APC unit has a 'knock' output where an LED

may be connected. This LED will then light up if knock is detected. The pictured APC gauge has this custom LED fitted at the end of the red scale. Because the knock sensor becomes less accurate at high revolutions, the APC tapers maximum boost pressure after approximately 4,500 RPM.

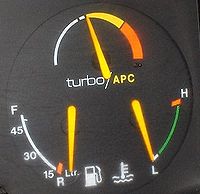

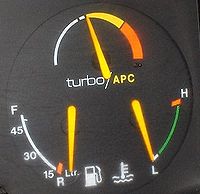

Saab Full Pressure Turbo (FPT) models with this unit include the APC name displayed on a non-numeric boost pressure gauge in the instrument panel. Although knock sensors are common even on non-turbocharged engines today, Saab has continued to use the APC name prominently as a differentiating feature.

Saab Full Pressure Turbo (FPT) models with this unit include the APC name displayed on a non-numeric boost pressure gauge in the instrument panel. Although knock sensors are common even on non-turbocharged engines today, Saab has continued to use the APC name prominently as a differentiating feature.

The white area on the left side of the scale shows manifold vacuum

under normal driving conditions, the short white dash is atmospheric pressure (engine off), the orange scale is where there is safe turbo boost, the red scale is boost above 0.5 - 0.7 bar

where the wastegate may be opened or a fuel cut due to knocking may occur.

Saab integrated the APC's boost control functionality with ignition control in 1990 with the introduction of the DI/APC system, available in 9000 models only. The DI/APC system managed knock not only by decreasing boost via a solenoid but by retarding ignition timing

as well; DI/APC also managed the engine's basic ignition timing.

Saab H engine

The Saab H engine is a redesign of the Saab B engine. Despite the name it is not an H engine, but a slanted inline-4. The H engine was introduced in 1981 in the Saab 900 and was also used in the Saab 99 from 1982 onwards and the Saab 90. It continued in use in the 900/9-3, 9000, and 9-5...

s in 1982 and was fitted to all subsequent 900 Turbos through 1993 (and 1994 convertibles), as well as 9000 Turbos through 1989.

Compression ratio

The 'compression ratio' of an internal-combustion engine or external combustion engine is a value that represents the ratio of the volume of its combustion chamber from its largest capacity to its smallest capacity...

(initially, 8.5:1 as opposed to 7.2:1, and, on 16-valve variants introduced in 1985, 9.0:1). This improved fuel economy

Fuel economy in automobiles

Fuel usage in automobiles refers to the fuel efficiency relationship between distance traveled by an automobile and the amount of fuel consumed....

and allowed the use of low-octane petrol without causing engine damage caused by knock

Engine knocking

Knocking in spark-ignition internal combustion engines occurs when combustion of the air/fuel mixture in the cylinder starts off correctly in response to ignition by the spark plug, but one or more pockets of air/fuel mixture explode outside the envelope of the normal combustion front.The...

.

The APC serves two purposes: it controls boost pressure - specifically, the rate of rise and maximum boost level - and it detects and manages harmful knock events.

To control the turbocharger, the APC monitors the engine's RPM

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

and inlet manifold

Inlet manifold

In automotive engineering, an inlet manifold or intake manifold is the part of an engine that supplies the fuel/air mixture to the cylinders...

pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

via a pressure transducer

Transducer

A transducer is a device that converts one type of energy to another. Energy types include electrical, mechanical, electromagnetic , chemical, acoustic or thermal energy. While the term transducer commonly implies the use of a sensor/detector, any device which converts energy can be considered a...

, and uses these inputs to control a solenoid valve that trims the rate of rise of pressure as well as the maximum pressure by directing boost pressure to the turbocharger's pneumatic wastegate actuator.

To detect knock, a piezoelectric knock sensor

Sensor

A sensor is a device that measures a physical quantity and converts it into a signal which can be read by an observer or by an instrument. For example, a mercury-in-glass thermometer converts the measured temperature into expansion and contraction of a liquid which can be read on a calibrated...

(basically a microphone

Microphone

A microphone is an acoustic-to-electric transducer or sensor that converts sound into an electrical signal. In 1877, Emile Berliner invented the first microphone used as a telephone voice transmitter...

) bolted to the engine block responds to unique frequencies caused by engine knock. The sensor generates a small voltage that is sent to the electronic control unit

Electronic control unit

In automotive electronics, electronic control unit is a generic term for any embedded system that controls one or more of the electrical systems or subsystems in a motor vehicle....

, which processes the signal to determine if, in fact, knock is occurring. If it is, then the control unit activates a solenoid valve that directs boost pressure to the turbocharger's pneumatically controlled wastegate

Wastegate

A wastegate is a valve that diverts exhaust gases away from the turbine wheel in a turbocharged engine system. Diversion of exhaust gases regulates the turbine speed, which in turn regulates the rotating speed of the compressor. The primary function of the wastegate is to regulate the maximum boost...

actuator, which opens the wastegate to bypass exhaust gases from the turbocharger directly to the exhaust pipe, lowering turbo boost pressure until the knock subsides. Knock events that are managed by the APC can be "seen" when the in-dash boost needle "twitches" slightly. The APC unit has a 'knock' output where an LED

LEd

LEd is a TeX/LaTeX editing software working under Microsoft Windows. It is a freeware product....

may be connected. This LED will then light up if knock is detected. The pictured APC gauge has this custom LED fitted at the end of the red scale. Because the knock sensor becomes less accurate at high revolutions, the APC tapers maximum boost pressure after approximately 4,500 RPM.

APC boost gauge

The white area on the left side of the scale shows manifold vacuum

Manifold vacuum

Manifold vacuum, or engine vacuum in an internal combustion engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere....

under normal driving conditions, the short white dash is atmospheric pressure (engine off), the orange scale is where there is safe turbo boost, the red scale is boost above 0.5 - 0.7 bar

Bar (unit)

The bar is a unit of pressure equal to 100 kilopascals, and roughly equal to the atmospheric pressure on Earth at sea level. Other units derived from the bar are the megabar , kilobar , decibar , centibar , and millibar...

where the wastegate may be opened or a fuel cut due to knocking may occur.

Saab integrated the APC's boost control functionality with ignition control in 1990 with the introduction of the DI/APC system, available in 9000 models only. The DI/APC system managed knock not only by decreasing boost via a solenoid but by retarding ignition timing

Ignition timing

Ignition timing, in a spark ignition internal combustion engine , is the process of setting the angle relative to piston position and crankshaft angular velocity that a spark will occur in the combustion chamber near the end of the compression stroke...

as well; DI/APC also managed the engine's basic ignition timing.